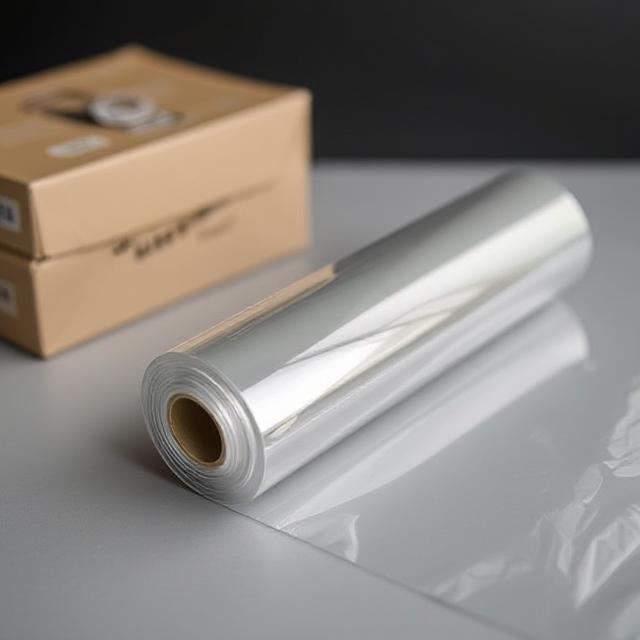

Packaging film is a versatile material used primarily in the packaging of products to protect, preserve, and enhance their appearance. It is a thin, flexible material that can be produced from a variety of substances, including plastic, paper, and even biodegradable materials. The primary function of packaging film is to safeguard goods from external factors such as moisture, dust, light, and physical damage during storage and transportation. It is an essential component in many industries, including food, pharmaceuticals, electronics, and consumer goods.

While the material itself is often transparent, allowing visibility of the packaged item, it can also be produced in various colors, textures, and finishes to suit specific branding and aesthetic needs. Packaging film can be molded into different shapes, sizes, and thicknesses, depending on the product it is designed to package.

Packaging film is a fundamental component of modern industries, playing a crucial role in the protection, preservation, and marketing of products. With the growing demand for convenience, efficiency, and sustainability, packaging film has become an essential tool for manufacturers across various sectors.

1. Product Protection and Preservation

One of the primary reasons packaging film is so important is its ability to protect products from a wide range of external factors. In industries like food, pharmaceuticals, and electronics, maintaining the integrity of the product is critical to ensuring quality and safety. Packaging film serves as a barrier against moisture, air, dirt, and contaminants, preserving the product's condition during storage, transport, and display.

For example, in the food industry, packaging film helps extend shelf life by protecting food from spoilage caused by exposure to oxygen, humidity, and light. Similarly, pharmaceutical products rely on packaging film to maintain sterility and prevent contamination. Whether it's fresh produce, over-the-counter medication, or high-tech gadgets, the protection provided by packaging film ensures that products reach consumers in optimal condition.

2. Cost Efficiency and Lightweight Solutions

Packaging film offers manufacturers a cost-effective solution compared to other traditional packaging materials like glass, metal, or cardboard. The lightweight nature of packaging film helps reduce transportation and storage costs, making it an economically viable option for large-scale production and distribution. This can be especially important for industries that ship products internationally, where shipping fees are often calculated based on weight.

Additionally, packaging film is often less expensive to produce and can be customized to meet specific packaging needs, further driving down costs. The flexibility to design film that fits the exact requirements of the product, while still maintaining quality and performance, provides businesses with significant savings without compromising on product protection or aesthetics.

3. Convenience and Efficiency in Packaging Operations

In the fast-paced world of manufacturing and distribution, efficiency is key. Packaging film streamlines the packaging process, offering flexibility and ease of use for manufacturers. It can be quickly applied, sealed, and transported, significantly reducing labor costs and production time compared to more rigid packaging options. The adaptability of packaging film allows it to conform to a wide range of product shapes and sizes, making it suitable for packaging diverse items—from food products to electronic devices.

Moreover, packaging film is compatible with automated packaging systems, enabling high-speed operations in production lines. This contributes to increased output and greater efficiency in manufacturing, making it an ideal choice for industries that need to meet large-scale demands and tight deadlines.

4. Aesthetic Appeal and Branding Opportunities

Packaging film provides manufacturers with a unique opportunity to enhance the visual appeal of their products. In industries like food and consumer goods, where product appearance plays a significant role in consumer decision-making, the clarity and versatility of packaging film can be a game-changer. Transparent films allow consumers to see the product inside, creating a sense of trust and confidence in the product's quality.

Additionally, packaging film can be easily printed with logos, product information, and marketing messages. Custom-designed films offer companies the ability to create distinctive, eye-catching packaging that stands out on store shelves, helping to reinforce brand identity and attract potential buyers. The ability to incorporate colors, patterns, and images into the packaging gives businesses a powerful tool for promoting their products and differentiating themselves from competitors.

5. Sustainability and Eco-Friendly Packaging

As environmental concerns continue to grow, industries are increasingly turning to sustainable packaging solutions. Packaging film has evolved to meet these concerns, with innovations in biodegradable, recyclable, and compostable materials becoming more prevalent. The shift toward eco-friendly packaging film helps reduce the environmental impact of packaging waste, addressing both consumer demand for sustainable products and regulatory pressures on businesses.

By adopting packaging films made from renewable resources or using recyclable materials, companies can lower their carbon footprint and contribute to a more sustainable circular economy. Furthermore, lightweight films that require less material to package products can help minimize waste, offering an environmentally responsible option that doesn't compromise on functionality.

6. Adaptability to Various Industries

Another reason packaging film is so important is its adaptability across different sectors. From food and beverages to pharmaceuticals, electronics, cosmetics, and even automotive parts, packaging film serves a wide variety of industries with diverse packaging needs.

In the food industry, packaging film ensures freshness, extends shelf life, and provides convenience for consumers. In the pharmaceutical sector, it guarantees the safe transport and handling of sensitive medical products. In electronics, it shields delicate components from moisture and dust. The flexibility of packaging film makes it a valuable asset for businesses in numerous fields, providing solutions tailored to each industry's unique requirements.

7. Consumer Safety and Compliance

In industries such as food and pharmaceuticals, packaging film plays a critical role in ensuring compliance with safety and regulatory standards. Proper packaging not only helps preserve the product's integrity but also protects consumers from potential hazards. Packaging film provides tamper-evident seals, preventing unauthorized access to products and ensuring that they are safe for consumption or use.

For instance, child-resistant packaging is increasingly common in pharmaceutical products, with packaging film being designed to offer enhanced safety features. Additionally, films used in food packaging often adhere to strict food safety standards, ensuring that the product inside remains uncontaminated and safe for consumption.

When choosing packaging film, there are several critical features that manufacturers and consumers alike should consider. The right packaging film can significantly affect the quality, safety, and appeal of a product, as well as influence its overall cost-effectiveness and environmental footprint.

1. Barrier Properties

One of the most important characteristics of packaging film is its ability to serve as a barrier against external elements. These elements can include moisture, air, light, and odors. Barrier properties are particularly crucial in industries like food, pharmaceuticals, and electronics, where the integrity of the product can be compromised by exposure to environmental factors.

Moisture Barrier: Ensures that products, particularly those in the food and pharmaceutical industries, remain dry and unaffected by humidity.

Oxygen Barrier: Helps prevent oxidation and spoilage, which is especially vital for perishable products.

UV Barrier: Protects products from harmful ultraviolet rays, which can degrade the quality and color of certain items, especially food and cosmetics.

2. Strength and Durability

The strength and durability of packaging film determine its ability to withstand external pressures, rough handling, and transportation stress. A strong film prevents punctures, tears, and breakages, ensuring that products reach consumers in perfect condition.

Tensile Strength: Refers to the film's ability to stretch without breaking, which is important for ensuring the package holds up under stress.

Impact Resistance: Packaging film should be resilient to impact, ensuring that the product is protected from damage during transportation or storage.

3. Flexibility

Flexibility is another key feature of packaging film. Unlike rigid containers, flexible films can be molded to fit a wide variety of shapes and sizes, making them suitable for packaging a broad range of products. This flexibility allows for custom shapes, easy sealing, and the potential for multiple layers to enhance functionality.

Shape Conformity: Packaging films can easily conform to the shape of the product, ensuring a tight seal and optimal protection.

Easy Handling: Flexible films are lightweight and easy to handle, which simplifies packaging processes and reduces labor costs.

4. Clarity and Aesthetic Appeal

For many products, particularly in the retail sector, the visual appeal of packaging plays a significant role in attracting consumers. Packaging film with high clarity allows consumers to see the product inside, which can be a selling point, especially for food and consumer goods.

Transparency: Clear films allow customers to inspect the product before purchase, ensuring product quality and boosting consumer confidence.

Printable Surface: Packaging film can be easily printed with branding, logos, and product information, allowing for customization to meet marketing goals.

5. Sealability

The ability of packaging film to form strong, secure seals is vital to ensuring product safety and extending shelf life. A well-sealed package helps preserve freshness, prevent contamination, and protect against tampering.

Heat Sealability: Many types of packaging films are heat-sealable, ensuring that the package remains securely closed during transit and storage.

Pressure Sealability: Some films offer the ability to form seals with pressure alone, making them ideal for certain types of packaging processes.

6. Sustainability

With growing concerns over environmental impact, sustainability is a significant consideration when selecting packaging materials. Many industries are turning to more eco-friendly packaging solutions, including biodegradable films, recyclable materials, and films made from renewable resources.

Recyclability: Packaging films that can be easily recycled contribute to a more sustainable packaging system and reduce waste.

Biodegradability: Some films are designed to break down naturally when exposed to environmental factors, offering an alternative to traditional plastic packaging.

Reduced Environmental Impact: Films that are lightweight, made from renewable sources, or require less energy in production contribute to reducing overall environmental impact.

7. Cost-Effectiveness

The cost of packaging film is always a crucial factor in selecting the right material. Manufacturers must balance the price of the film with the benefits it offers, ensuring that the film meets the functional requirements of the product while staying within budget.

Material Cost: Different films come at various price points, and manufacturers need to choose the one that offers the best value based on performance and application.

Efficiency: Films that require less material for the same level of protection can help reduce costs, making them an attractive option for large-scale production.

8. Customization Options

Packaging film can be customized to meet the specific needs of different products and industries. Customization may include different colors, textures, finishes, and even printed branding elements.

Custom Colors and Prints: Companies can choose packaging films in a range of colors to match their branding or use printed film to convey product information, marketing messages, or instructions.

Special Coatings and Finishes: Some packaging films come with coatings or finishes that enhance properties like gloss, matte, or anti-scratch features, adding to both aesthetics and functionality.

Packaging film plays a vital role in the packaging industry, offering a wide variety of materials suited to different product requirements. The type of packaging film selected for a particular product largely depends on its purpose, the product’s nature, and environmental considerations.

1. Polyethylene (PE) Film

Polyethylene is one of the most common and widely used packaging films, available in both low-density (LDPE) and high-density (HDPE) varieties. Known for its flexibility, durability, and cost-effectiveness, polyethylene film is versatile and can be used for a wide range of applications.

Applications:

Food Packaging: Polyethylene film is often used to package fresh produce, bakery items, and snacks due to its ability to form tight seals and provide moisture resistance.

Shrink Wrap: It is used for shrink-wrapping products to secure them during transit and storage.

Consumer Goods: PE films are also commonly used to wrap consumer products like toys, books, and non-food items.

The main advantage of PE film is its ability to offer a barrier against moisture and contaminants while maintaining flexibility and ease of use in various packaging formats.

2. Polypropylene (PP) Film

Polypropylene is another popular packaging material due to its strength, clarity, and high resistance to chemicals. PP films are transparent, which makes them an ideal choice when visual appeal is important, such as in retail packaging. It is known for its excellent heat resistance, which makes it ideal for applications requiring sterilization or high-temperature exposure.

Applications:

Food Packaging: Commonly used for packaging snack foods, confectionery, and ready-to-eat meals. PP film offers a high degree of freshness retention, helping to extend the shelf life of perishable items.

Medical Packaging: PP films are used in pharmaceutical and medical applications where sterilization is essential, such as packaging syringes, bandages, or medical instruments.

Cosmetic and Personal Care Products: PP is also used in packaging items like shampoos, lotions, and other cosmetic products due to its ability to maintain product integrity and offer a glossy, attractive finish.

The transparency and ability to resist high temperatures make PP films a preferred choice in many high-end and consumer-focused packaging solutions.

3. Polyvinyl Chloride (PVC) Film

PVC films are another common type of packaging film known for their durability and versatility. They come in both rigid and flexible forms, with the flexible variant being used in a wide range of packaging applications. PVC is often chosen for its ability to provide excellent clarity, impact resistance, and aesthetic appeal.

Applications:

Food Packaging: PVC is often used in the food industry for packaging fresh meats, cheeses, and other perishable items that require a strong barrier against air and moisture.

Retail Packaging: PVC is commonly used for clamshell packaging, which securely holds and displays products like electronics, tools, and toys in retail settings.

Pharmaceuticals: Flexible PVC film is also used in blister packs for tablets and capsules, providing a tamper-proof and protective barrier to keep medication safe and secure.

While it is known for its clarity and rigidity, PVC also offers a reliable seal to keep products safe during storage and shipping.

4. Polyester (PET) Film

Polyester films, particularly polyethylene terephthalate (PET), are known for their strength, resistance to moisture, and excellent dimensional stability. PET films are often used when high-performance and protection are required, such as in the packaging of products that need a strong barrier to oxygen and moisture.

Applications:

Food Packaging: PET films are widely used in the food packaging industry, particularly for products like dried fruits, snacks, and beverages, where maintaining freshness is essential.

Electronics Packaging: PET films are used to package sensitive electronic components and devices, offering protection against moisture, static, and dust.

Beverage Packaging: PET films are commonly used for creating bottles and pouches for beverages, due to their ability to withstand pressure and maintain product integrity.

PET film is valued for its high strength, clarity, and resistance to environmental factors, making it an ideal choice for products that require durable and long-lasting packaging.

5. Biaxially Oriented Polypropylene (BOPP) Film

BOPP is a type of polypropylene film that has been stretched in two directions to enhance its strength and clarity. This film is widely recognized for its high tensile strength, resistance to moisture, and ability to provide a protective barrier against gases and aromas. BOPP film is also highly printable, making it ideal for branding and marketing purposes.

Applications:

Food Packaging: BOPP is commonly used for packaging snacks, frozen foods, and confectionery. Its ability to preserve freshness while offering a clear, attractive view of the product makes it popular in consumer goods packaging.

Labeling: BOPP film is often used as a labeling material due to its excellent printability and durability.

Tapes and Adhesive Films: The enhanced strength and stretchability of BOPP make it a popular choice for packaging tapes and adhesive films used in the industrial sector.

The versatility, strength, and aesthetic qualities of BOPP film have made it a popular choice for both consumer packaging and industrial applications.

6. Biodegradable and Compostable Films

With increasing awareness of environmental issues, biodegradable and compostable films have gained popularity in packaging applications. These films are made from renewable resources and break down naturally over time, making them a more eco-friendly alternative to traditional plastic films.

Applications:

Food Packaging: Biodegradable films are used for packaging products like fresh produce, bakery goods, and snacks, offering a sustainable option that reduces plastic waste.

Single-Use Packaging: Items like straws, cutlery, and food trays are increasingly being packaged in compostable films to address environmental concerns about plastic pollution.

Consumer Goods: Biodegradable films are also used for packaging eco-friendly products in a variety of sectors, including cosmetics and cleaning supplies.

| Type of Packaging Film | Key Characteristics | Applications |

|---|---|---|

| Polyethylene (PE) Film | Flexible, durable, cost-effective | - Food packaging (produce, snacks) - Shrink wrap - Consumer goods (toys, books) |

| Polypropylene (PP) Film | Transparent, strong, heat-resistant | - Food packaging (snacks, ready meals) - Medical packaging (syringes, bandages) - Cosmetics packaging (shampoos, lotions) |

| Polyvinyl Chloride (PVC) Film | Durable, clear, impact-resistant | - Food packaging (meats, cheeses) - Retail packaging (electronics, toys) - Pharmaceutical blister packs |

| Polyester (PET) Film | Strong, moisture-resistant, dimensionally stable | - Food packaging (dried fruits, snacks) - Electronics packaging - Beverage packaging |

| Biaxially Oriented Polypropylene (BOPP) Film | High tensile strength, clear, highly printable | - Food packaging (snacks, confectionery) - Labeling - Tapes and adhesive films |

| Biodegradable and Compostable Films | Made from renewable resources, eco-friendly | - Food packaging (produce, bakery goods) - Single-use packaging (straws, cutlery) - Consumer goods packaging (cosmetics, cleaning supplies) |

Packaging films come in a wide range of materials, each with distinct properties that make them suitable for different types of products and applications. Below, we will highlight the key differences between various types of packaging film, including their characteristics, benefits, and typical uses.

| Type of Packaging Film | Material | Key Characteristics | Typical Applications |

|---|---|---|---|

| Polyethylene (PE) Film | Polyethylene (PE) | - Flexible and durable - Lightweight - Excellent moisture barrier - Low cost |

- Food packaging (e.g., fruits, vegetables) - Shrink wrapping - Packaging for consumer goods (e.g., books, toys) |

| Polypropylene (PP) Film | Polypropylene (PP) | - High strength - Transparent and glossy - Resistant to heat - Good moisture and chemical resistance |

- Food packaging (e.g., snacks, confectionery) - Pharmaceutical packaging - Cosmetic packaging |

| Polyvinyl Chloride (PVC) Film | Polyvinyl Chloride (PVC) | - Rigid or flexible - Excellent clarity and transparency - Strong and impact-resistant - Good barrier against moisture and oxygen |

- Retail packaging (e.g., clamshell packaging) - Medical blister packs - Food packaging (e.g., meats, cheeses) |

| Polyester (PET) Film | Polyester (PET) | - Strong and durable - Excellent moisture, heat, and chemical resistance - High dimensional stability - Can be recycled easily |

- Food packaging (e.g., dried fruits, snacks) - Electronics packaging - Beverage bottles and pouches |

| Biaxially Oriented Polypropylene (BOPP) Film | Polypropylene (PP) | - Stretchable and strong - High tensile strength - Clear and glossy finish - Printable surface - Resistant to moisture, oils, and grease |

- Food packaging (e.g., chips, candies) - Labeling - Tapes and adhesive films |

| Biodegradable and Compostable Films | Various biodegradable materials (e.g., PLA, PHA) | - Eco-friendly - Made from renewable resources - Biodegradable or compostable - Offers a sustainable alternative to traditional plastic films |

- Food packaging (e.g., produce, bakery goods) - Single-use packaging (e.g., straws, cutlery) - Consumer goods packaging |

Key Differences:

Material Composition:

Each type of packaging film is made from different base materials, such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polyester (PET), and biodegradable materials. This influences the film's overall strength, flexibility, and protective properties.

Barrier Properties:

Different films provide varying levels of protection against moisture, gases, and light. For example, polyethylene is a good moisture barrier, whereas polyester offers superior chemical and heat resistance. Biodegradable films may provide a lower barrier against gases but are environmentally friendly alternatives.

Strength and Durability:

PET and BOPP films are known for their high strength and durability, making them ideal for products that need a strong protective layer. PVC and PE films, on the other hand, are more flexible but may not offer the same level of physical protection.

Clarity and Aesthetic Appeal:

Films like polypropylene (PP) and PVC provide excellent clarity and a glossy finish, making them suitable for products where visibility and presentation are important, such as food and consumer goods packaging. BOPP is also a popular choice for its high clarity and printability.

Environmental Considerations:

Traditional films like PE, PP, and PVC may take a long time to degrade, contributing to plastic pollution. In contrast, biodegradable and compostable films are made from renewable resources and break down naturally, making them more sustainable options for eco-conscious consumers and businesses.

Cost and Customization:

Polyethylene (PE) and polypropylene (PP) films are typically more affordable, making them ideal for high-volume, cost-sensitive applications. In contrast, films like PET and PVC, while offering superior strength or clarity, may be more expensive.

Choosing the right packaging film is a critical decision that can significantly impact the effectiveness, cost, and sustainability of the packaging process. The right film not only protects the product but also helps enhance its shelf appeal, extends its shelf life, and meets regulatory requirements. With a wide variety of packaging films available, selecting the most suitable one requires careful consideration of several factors.

1. Consider the Product Type and Its Requirements

The first step in selecting the right packaging film is to understand the specific needs of the product being packaged. Different products have different packaging requirements based on their size, shape, fragility, shelf life, and sensitivity to environmental factors like moisture, light, or oxygen.

Food Products: Food packaging films should offer protection against moisture, oxygen, and contaminants while ensuring the product’s freshness and safety. Depending on whether the product is perishable or long-lasting, the film chosen will vary. For example, films for fresh produce need to be breathable, while those for dry snacks require a high barrier against air and humidity.

Pharmaceuticals: For pharmaceuticals, packaging films must maintain sterility, protect the product from tampering, and meet regulatory standards. Films used for medications may need to be airtight or even tamper-evident to ensure the product remains uncontaminated.

Electronics and Consumer Goods: Packaging films for electronics or fragile items must be robust enough to provide physical protection while remaining lightweight and cost-effective. These films often offer resistance to moisture and static.

Cosmetics: Cosmetic packaging often requires clear, attractive films that enhance product visibility while also providing protection from contaminants. The packaging should also be able to maintain the product's integrity over time.

Each product will have unique requirements based on its usage, handling, and shelf life, which will influence the type of film chosen.

2. Evaluate Barrier Properties

Barrier properties refer to the ability of the packaging film to protect the product from external factors such as moisture, light, air, and gases. Packaging films with excellent barrier properties are particularly essential in industries like food, pharmaceuticals, and chemicals.

Moisture and Oxygen Barrier: If the product is sensitive to moisture or oxidation, you will need a film with high moisture and oxygen barrier properties. For instance, products like chips or meat require films that prevent air and moisture from entering, thus extending their shelf life.

UV Light Protection: Some products, such as cosmetics or certain foods, can degrade under UV light exposure. A film that offers UV protection will preserve the product's quality by preventing exposure to sunlight or artificial light.

Gas Barrier: Some products, particularly fresh food, need films that control the exchange of gases like carbon dioxide and oxygen. This helps maintain freshness and extend the product's shelf life.

Evaluating the barrier properties of different films is crucial to ensure that the packaging protects the product effectively while keeping it safe during storage and transportation.

3. Consider the Strength and Durability of the Film

The physical properties of the packaging film should be assessed to ensure that it can withstand the rigors of handling, transport, and storage. Packaging film needs to be strong enough to prevent punctures, tears, or damage while being handled during manufacturing, distribution, and storage.

Tensile Strength: Packaging film should have sufficient tensile strength to resist breaking under stress or stretching during the packaging process. Films used for heavy or bulky products need to be particularly durable.

Impact Resistance: The film should offer impact resistance to protect the product from damage during transportation and handling. This is particularly important for fragile products, such as electronics or glass items.

Stretchability: Films used for shrink wrapping or stretch films need to have good elongation properties to conform to the shape of the product while still providing a tight, secure seal.

Strength and durability are vital in maintaining the safety and integrity of the product during its journey through the supply chain.

4. Assess the Aesthetic and Branding Needs

Packaging is not just about protection—it's also about making a strong impression on consumers. The visual appeal of the packaging can influence a consumer’s decision to purchase a product. Packaging film offers a range of options to enhance the look of the product while keeping it safe.

Transparency: Clear films are often preferred for products where visibility is important, such as food items or consumer goods. Transparency allows the consumer to inspect the product before purchasing, which helps build trust.

Customizability: Many types of packaging films can be printed with logos, product information, and promotional messages. Customizing the packaging film helps reinforce brand identity and communicate key product features or instructions to the consumer.

Finish and Texture: Films come in different finishes, including glossy, matte, or textured options. The finish of the packaging film can influence how the product is perceived by consumers. For example, a matte finish can convey sophistication, while a glossy finish can attract attention and highlight the product’s appearance.

By choosing packaging film that aligns with aesthetic preferences, businesses can make their products stand out on store shelves and connect with consumers.

5. Consider Sustainability and Environmental Impact

In today's market, consumers and businesses are increasingly concerned with sustainability. Packaging film is no exception, and the choice of film material can have a significant impact on the environment. Companies are now looking for more eco-friendly packaging solutions that minimize waste and reduce environmental impact.

Recyclability: If sustainability is a priority, selecting recyclable packaging film is a great option. Many types of packaging films are recyclable, allowing businesses to contribute to reducing waste in landfills.

Biodegradable Films: For a more eco-conscious approach, biodegradable films made from plant-based materials are available. These films break down naturally over time, offering a sustainable alternative to traditional plastic films.

Reduced Material Usage: Using thin films that still offer adequate protection can reduce the amount of material required, contributing to a more efficient use of resources and minimizing packaging waste.

By opting for eco-friendly packaging film, businesses can align with consumer preferences for sustainability and contribute to environmental conservation.

6. Cost and Performance Balance

While the performance of packaging film is essential, businesses must also consider the overall cost. The selected film should provide the necessary protection and meet the product's needs without exceeding budget constraints.

Cost Efficiency: Packaging films come in a range of prices, and selecting the right film involves balancing cost and performance. Some films may be more expensive but provide superior protection or aesthetics, while others may be more budget-friendly for products that do not require heavy-duty protection.

Long-Term Value: The long-term performance of packaging film should also be considered. Choosing a film that provides superior protection and extends the product's shelf life can reduce waste and increase customer satisfaction, providing better overall value in the long run.

The packaging industry is continuously evolving, driven by consumer demand for more sustainable, functional, and visually appealing solutions. As technology advances and environmental concerns grow, the latest innovations and trends in packaging film are reshaping how products are packaged, transported, and presented.

1. Sustainable Packaging Solutions

Sustainability has become a central focus in packaging film innovation, driven by consumer preference for eco-friendly products and increasing regulatory pressure. Companies are now focusing on developing packaging films that minimize environmental impact and offer recycling or composting options.

Biodegradable and Compostable Films: The demand for biodegradable and compostable films made from plant-based materials, such as PLA (Polylactic Acid) and PHA (Polyhydroxyalkanoates), is on the rise. These materials break down naturally, offering a more sustainable alternative to traditional plastic films.

Recycled Content Films: Packaging films made from recycled materials, such as recycled PET (rPET) and polyethylene, are gaining popularity. These films help reduce the reliance on virgin plastic and encourage a circular economy.

Minimalist Packaging: Companies are focusing on using less material in packaging while still offering the same protective qualities. Films designed to use less plastic while maintaining strength and barrier properties are becoming more common, contributing to a reduction in packaging waste.

Sustainability is driving significant changes in the packaging film market, with an increasing emphasis on reducing waste, conserving resources, and offering consumers eco-friendly options.

2. Smart Packaging Films

Smart packaging is becoming an integral part of the packaging film industry, offering enhanced functionality through the integration of technology. These films go beyond traditional packaging, providing consumers and manufacturers with more control and information about the products they purchase or produce.

Active Packaging Films: Active packaging films are designed to interact with the product they enclose. For example, films with antimicrobial properties can prevent the growth of bacteria and mold in food packaging, thereby extending shelf life.

Intelligent Packaging: Intelligent packaging films incorporate sensors that monitor environmental conditions such as temperature, humidity, or exposure to light. These films can alert consumers or suppliers if the product has been compromised during transport or storage, ensuring product integrity.

QR Codes and NFC Technology: Packaging films embedded with QR codes or NFC (Near Field Communication) chips enable consumers to access product information, track the supply chain, or even authenticate the product. This trend not only enhances transparency but also boosts consumer trust and engagement.

Smart packaging films are transforming the way products are packaged, offering both enhanced consumer experience and better control over product quality throughout the supply chain.

3. Barrier Coating Innovations

The importance of barrier properties in packaging film is crucial, especially for industries such as food and pharmaceuticals. Innovations in barrier coatings are improving the ability of packaging films to protect products from external factors such as moisture, oxygen, and UV light, without relying on traditional plastic materials.

Water-Based Barrier Coatings: New, water-based coatings are being developed to offer moisture resistance without the need for chemical-based coatings. These eco-friendly alternatives are biodegradable and safer for both consumers and the environment.

Nano-coatings: Nano-technology is being applied to packaging films to enhance barrier properties, increase durability, and reduce the thickness of the film while maintaining its protective qualities. Nano-coatings can improve the resistance of films to oxygen, moisture, and heat, providing longer shelf life for food and sensitive products.

These innovative barrier coatings are contributing to the creation of packaging films that provide superior protection, better performance, and reduced environmental impact.

4. Flexible and Lightweight Films

The trend towards lighter, more flexible packaging materials continues to grow as businesses seek ways to reduce shipping costs and minimize waste. Flexible and lightweight packaging films are not only more efficient but also easier to handle and process.

Flexible Packaging: Films that can be easily molded, stretched, or sealed are increasingly popular in industries like food and beverage packaging, as well as consumer goods. Flexible packaging can reduce the need for bulky containers, resulting in lower material use and reduced transportation costs.

Lightweight Films: Advances in film technology have led to the development of thinner, stronger films that require less material to package the same product. These lightweight films help reduce the carbon footprint associated with production and transportation while maintaining the protective qualities of thicker films.

This trend towards lightweight, flexible films is helping businesses lower costs, increase efficiency, and reduce their environmental impact.

5. Enhanced Printing and Customization

As packaging plays a crucial role in marketing, companies are focusing on packaging films that can be customized with high-quality prints and unique designs. This trend is helping brands differentiate their products on the shelf and improve consumer engagement.

High-Quality Printing: Advances in printing technology, such as digital printing and flexographic printing, have made it easier to print detailed designs on packaging films. High-quality prints can showcase vibrant colors, intricate patterns, and branding elements that help attract customers.

Personalized Packaging: Customization is key in today’s competitive market. Packaging films that can be easily adapted to different sizes, shapes, and designs are in demand, allowing businesses to cater to a wide range of customer preferences. Personalized packaging not only enhances the product’s appeal but also helps businesses strengthen their brand identity.

These innovations in printing and customization are allowing businesses to create unique, attention-grabbing packaging that resonates with consumers.

6. Recyclability and Circular Economy

The push for a circular economy is driving the development of packaging films that are easier to recycle and can be reused in the production of new packaging materials. Recyclable packaging films are becoming more advanced, with improved designs that make them easier to collect and process.

Single-Material Films: Manufacturers are focusing on creating packaging films made from a single material to simplify recycling processes. These films can be processed more easily in recycling plants, reducing contamination and improving recycling rates.

Chemical Recycling: Chemical recycling technologies are being developed to recycle plastics that were previously not recyclable through traditional methods. These technologies allow packaging films to be broken down and reused, contributing to a closed-loop system.

The trend toward recyclability and a circular economy is reshaping the packaging film industry, offering more sustainable packaging solutions and reducing waste.

The latest innovations and trends in packaging film are driven by the need for more sustainable, efficient, and consumer-friendly packaging solutions. From eco-friendly materials and smart packaging technologies to improved barrier coatings and customization options, packaging films are evolving to meet the demands of modern industries. As businesses seek to improve product protection, reduce environmental impact, and enhance consumer experience, these innovations are paving the way for the future of packaging.

For more information on cutting-edge packaging solutions, visit jtpackage.com, where we specialize in providing high-quality, sustainable packaging film options for a wide range of industries.