Product Advantages

Excellent anti-fog performance: Designed for refrigerated or high humidity environments, it uses cross-linking technology and anti-fog additives to ensure that the packaging surface does not form water beads at low temperatures and maintains clear visibility. Even if you package water-containing items (such as meat, fruits and vegetables), you can still clearly display product details after refrigeration to enhance shelf appeal.

High strength and cold resistance: The tensile strength is as high as 130-140N/mm² (MD direction), and the tear resistance is excellent, which is 50% stronger than ordinary POF film. It has a wide cold temperature range and can adapt to -40℃ to 130℃ environments. The shrinkage rate is as high as 20%-81% (100-130℃), which fits tightly to special-shaped products and reduces packaging damage.

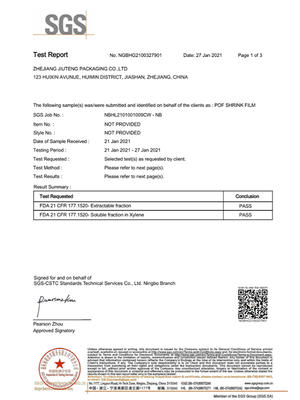

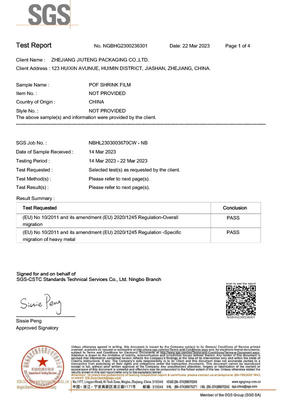

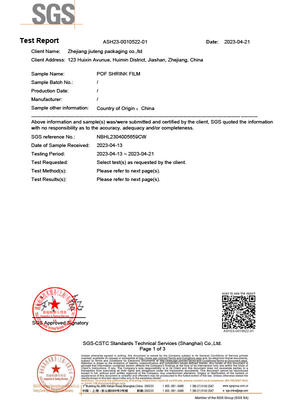

Environmental protection and safety certification: It complies with FSSC22000 food safety system certification and is suitable for direct food contact packaging. It uses recyclable polyolefin materials, and some products support bio-based raw materials to reduce environmental burden.

Application Scenarios

Fresh food: Refrigerated packaging of meat, fruits and vegetables, dairy products, etc., with long-lasting anti-fog effect and extended shelf life.

Industrial products: electronic products, gift boxes, books and other special-shaped items packaging, high shrinkage rate to ensure tight protection.

Automated production line: suitable for high-speed packaging machines, wide heat sealing temperature range (100-130℃), firm sealing and high efficiency.

Technical Parameters

Thickness selection: 12µm, 15µm, 19µm , 25µm.

Transparency>93%, haze<5.4, gloss>77, to ensure product display effect.

Anti-fog time: effective in 2 hours, long-term transparent and fog-free.

简体中文

简体中文

Home

Home