Packaging choices matter more today than ever before. Companies face pressure to pick materials that protect products without adding unnecessary burden to the environment. Polyolefin shrink film, often called POF, has gained attention in this space. It wraps items tightly after heat exposure, creating a clean, secure package. Many businesses now turn to it because it balances performance with lower environmental impact.

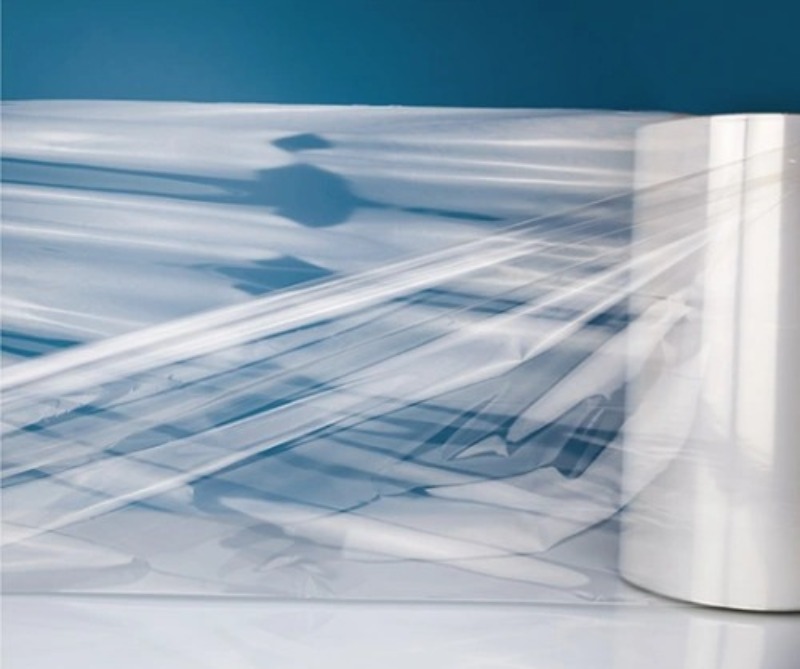

POF shrink film comes from polyolefin resins, mainly polyethylene and polypropylene blends. These polymers get extruded into thin, flat sheets during manufacturing. When exposed to heat, the film shrinks evenly around the product, forming a close-fitting barrier. That barrier guards against dust, moisture, and minor physical damage.

People notice its high clarity right away. Items stay clearly visible through the wrap, which helps with product display on shelves. The film also shows good puncture resistance and tear strength for its thickness. It handles irregular shapes reasonably well without splitting.

Another point worth mentioning is the lack of certain harsh additives. POF avoids chlorine-based compounds that appear in some older films. This simpler makeup reduces complications during both use and disposal phases. Overall, the basic chemistry lays a solid foundation for its environmental profile.

One strong reason people call POF eco-friendly centers on its ability to enter recycling streams. After use, the film can go back into collection systems designed for polyolefin plastics. Facilities process it into pellets that become new packaging or other goods.

Sorting happens smoothly because POF shares resin codes with common plastics already in widespread recycling programs. That compatibility keeps contamination low and recovery rates higher. Companies that collect used film from their operations often find it fits existing infrastructure without major changes.

Using less material per package adds another layer of benefit. Thinner gauges still deliver solid protection in most cases. Fewer raw inputs mean less extraction from the earth. Lighter packages also cut fuel needs during transport, trimming emissions along the supply chain.

Traditional shrink films sometimes include chlorine, which raises concerns during burning or breakdown. POF skips those elements entirely. No chlorine means no dioxins or similar toxins form when the material faces high heat or accidental incineration.

Food-related industries value this trait especially. Packaging that touches consumables must avoid migrating anything unwanted. POF meets many regulatory requirements in that area because of its cleaner makeup. Handlers face fewer risks too during daily operations.

Even in landfill scenarios, the lack of heavy additives lowers the chance of long-term leaching into groundwater. While proper recycling remains the good path, this reduced hazard profile still marks an improvement over alternatives that carry greater risks.

Production of POF shrink film demands relatively moderate energy levels. Extrusion and orientation steps run at temperatures lower than those needed for certain competing materials. That difference adds up across large-scale runs.

The shrinking process itself works at practical heat settings. Most standard heat tunnels or guns reach the required range without excessive power draw. Packaging lines therefore consume less electricity overall compared with films needing higher temperatures.

From raw resin to final sealed package, the entire chain shows thoughtful energy use. Industries aiming to shrink their carbon footprint find this consistency appealing. It allows meaningful progress without forcing complete equipment overhauls.

Placing POF side by side with alternatives clarifies its position.

| Aspect | POF Shrink Film | PVC Shrink Film |

|---|---|---|

| Base ingredients | Olefin-based, no chlorine | Contains chlorine plus stabilizers |

| Recycling ease | Fits standard polyolefin streams | Complicated by chlorine content |

| Toxicity profile | Low risk of harmful emissions | Potential for toxic gas release when burned |

| Production energy | Moderate requirements | Generally higher |

| End-of-life impact | Supports reuse and lower pollution | Greater chance of persistent issues |

The contrast becomes clear in several categories. POF consistently shows advantages where environmental performance gets measured. Many decision-makers weigh these points when updating packaging specifications.

Food producers rely on POF for fresh produce, bakery items, and ready meals. The wrap keeps contents clean while letting shoppers see exactly what sits inside. Its food-contact approval adds confidence for brands in that space.

Electronics and small appliances often get bundled with POF. The film holds multiple pieces together securely without extra boxes or foam. That reduction in secondary materials cuts overall waste volume noticeably.

Toys and games use it for retail display packs. Clear presentation draws attention on shelves, and the tamper-evident seal provides reassurance. Recyclability aligns well with family-oriented brands pushing greener messages.

Beverage multipacks represent another common application. Several bottles or cans stay grouped tightly, reducing the need for trays or heavier wraps. Distribution becomes simpler and lighter as a result.

E-commerce operations appreciate POF for its durability during shipping. Lightweight yet tough, it withstands handling while keeping parcel size compact. Lower dimensional weight helps control freight expenses too.

Adopting any new material brings practical questions. Some older machines need minor tweaks to handle POF optimally, although most modern equipment runs it without trouble. Trial runs usually reveal needed adjustments quickly.

Initial pricing sometimes sits higher than conventional options. Yet savings in waste disposal, energy bills, and potential regulatory fees can balance the equation over time. Many users report net gains after the first year.

Workers need basic guidance on sorting and recycling used film. Clear instructions at the facility level ensure recovery rates. When everyone understands the process, the environmental loop closes more effectively.

Material developers keep refining POF formulations. Some newer grades incorporate post-consumer content without losing key properties. Those versions push recyclability even further.

Stricter rules around single-use plastics appear in various regions. Films like POF that fit recycling infrastructure stand a better chance of remaining compliant long-term. Forward-thinking companies monitor these changes closely.

Shoppers show growing interest in packages labeled as recyclable. Brands using POF can communicate that benefit more easily. Honest messaging about end-of-life options builds trust with conscious buyers.

Combining POF with lighter designs and returnable systems creates stronger sustainability results. The material fits neatly into broader strategies that look beyond single packages. That flexibility keeps it relevant as priorities evolve.

POF shrink film earns its eco-friendly label through practical advantages rather than marketing claims. Recyclability, clean composition, and efficient production form a solid foundation. It serves many industries without forcing major trade-offs in protection or appearance.

Businesses searching for dependable POF shrink film often value suppliers who focus on consistent quality and environmental alignment. JTPackage produces rolls designed for real-world performance across food, retail, and industrial needs. Their approach emphasizes durability while supporting responsible use.

Working with JTPackage gives access to films that help meet sustainability targets without sacrificing reliability. The team brings practical knowledge to every order, assisting clients in selecting suitable options. Many companies find this combination of quality and care makes a meaningful difference in their packaging efforts.