In the world of packaging, Polyolefin Shrink Film has become a game changer, offering unparalleled versatility, strength, and clarity. Whether you're in retail, manufacturing, or food industries, this high-performance film is the unsung hero that wraps, protects, and displays products with unmatched precision. Known for its superior shrinkability, durability, and eco-friendly properties, polyolefin shrink film is rapidly becoming the go-to solution for businesses looking to optimize their packaging processes. But what makes it stand out from other films on the market? How does it work, and why is it so popular? In this article, we'll explore the ins and outs of polyolefin shrink film, breaking down its key features, benefits, and applications. Get ready to discover why this film could be the ultimate solution for your packaging needs.

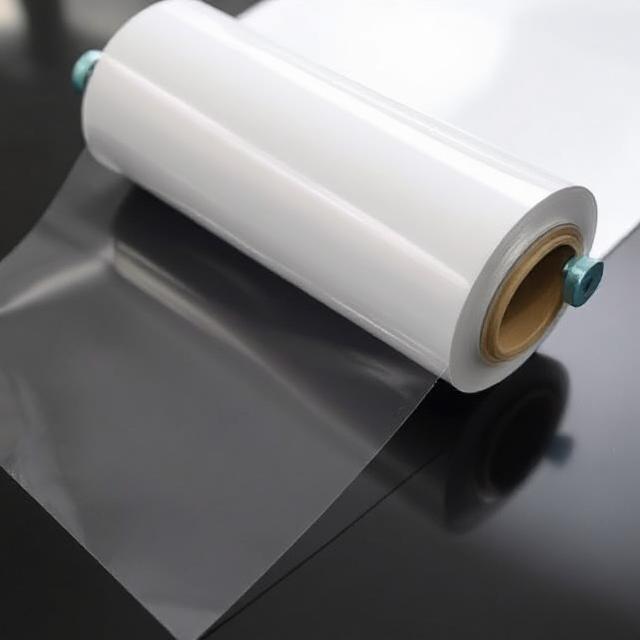

Polyolefin Shrink Film is a versatile, high-quality packaging material used extensively in various industries due to its exceptional clarity, durability, and eco-friendly properties. Made from a combination of polyolefin polymers like polyethylene and polypropylene, this film is designed to shrink tightly around a product when exposed to heat, providing a protective and visually appealing packaging solution.

Here's an in-depth look at what POF shrink film is and why it's widely preferred in the packaging industry:

POF stands for Polyolefin, a type of thermoplastic polymer commonly used in the production of shrink film. Polyolefin shrink film is widely used in packaging due to its versatility, strength, and environmentally friendly properties. It is considered a preferred alternative to traditional PVC (polyvinyl chloride) shrink film for several key reasons.

Polyolefin shrink film is made from a blend of polyolefin materials like polyethylene and polypropylene, which are known for their excellent shrinkage properties when exposed to heat. When the film is heated, it shrinks tightly around the product, providing a secure and protective seal.

Compared to PVC shrink film, POF shrink film offers several benefits:

Eco-friendly:

Unlike PVC films, POF shrink films are non-toxic and recyclable. This makes them an environmentally responsible option, as they are free from harmful chemicals like chlorine and are safer for both consumers and the planet.

Safety:

POF shrink films are safer to handle than PVC, which can release toxic fumes when heated. The absence of harmful substances like chlorine makes POF a much safer choice for both manufacturers and consumers.

Superior Clarity and Durability:

Polyolefin shrink films provide excellent clarity, making the packaged product easily visible and visually appealing. The film also offers superior strength, providing excellent protection against tears, punctures, and abrasions during handling and transit.

Heat Resistance:

POF films are known for their excellent heat resistance. They can withstand high temperatures during the shrink-wrapping process without becoming brittle, ensuring a secure and durable seal around the product.

Polyolefin shrink film stands out as an excellent packaging solution due to its unique combination of features. Here are some key properties that make Polyolefin (POF) shrink film a popular choice across various industries:

1. High Clarity

POF shrink film offers outstanding transparency, allowing the packaged product to be easily visible. This feature enhances the product’s shelf appeal, making it more attractive to consumers in retail settings. The clear film showcases the product's design, branding, and packaging details effectively, ensuring a visually appealing presentation.

2. Strong Seal Strength

Polyolefin shrink film is known for its superior sealing capabilities. When heat is applied, it forms strong, tamper-evident, and secure seals that protect the product from contamination and damage. These robust seals ensure the integrity of the product, offering protection from tampering and preventing moisture or dirt from entering.

3. Excellent Tear Resistance

Unlike PVC shrink film, POF shrink film is less prone to tearing or becoming brittle, even in high-stress conditions. Its tear-resistant nature makes it an ideal choice for packaging products that will be handled frequently or transported over long distances, ensuring that the packaging remains intact and durable.

4. FDA Approved

Many types of Polyolefin shrink films are FDA-approved, which means they are safe for food packaging applications. This makes POF shrink film an ideal choice for wrapping consumables, ensuring the safety and quality of the product while complying with health regulations.

5. Low Odor

POF shrink film produces minimal odor when heated, which is a significant advantage over other materials like PVC. The low emission of fumes makes it safer and more comfortable for operators, creating a healthier working environment and minimizing unpleasant smells during the shrink-wrapping process.

6. More Eco-Friendly

One of the standout features of POF shrink film is its environmental friendliness. Unlike PVC, which can release harmful chemicals during production and disposal, Polyolefin is considered more eco-friendly. It is often recyclable and has a lower overall environmental impact, making it a more sustainable packaging option for businesses focused on reducing their carbon footprint.

Polyolefin (POF) shrink film is produced through a specialized process that transforms polyolefin resins into a highly versatile and protective packaging material. Here’s a breakdown of the steps involved in creating POF shrink film:

1. Material Creation

The process begins with polyolefin resins, which are the primary raw materials for POF shrink film. These resins are heated and melted down to create a smooth, pliable material suitable for further processing.

2. Extrusion

Once the polyolefin resin is melted, it is forced through a die using an extrusion process. The extrusion mold shapes the molten resin into a thin film. This step is critical in determining the film's thickness and overall quality.

3. Cooling

After extrusion, the thin film passes through a cooling system where it rapidly cools and solidifies. This quick cooling process helps set the shape and ensures the film maintains its desired properties such as clarity and flexibility.

4. Winding

Once the film has been cooled and solidified, it is wound onto large rolls. These rolls serve as the material that will be used in packaging. Winding ensures that the film is stored compactly and ready for use in manufacturing or distribution.

5. Heat Application

When it's time to use the film, it is wrapped around the product that needs packaging. Heat is then applied to the film, typically in the form of hot air or a heat tunnel. The heat causes the film to expand slightly and then shrink tightly around the product.

6. Shrinkage

The heat triggers the shrinkage process. As the film is exposed to heat, it shrinks tightly, conforming to the shape of the item being wrapped. This creates a secure, protective seal that holds the product firmly in place and provides a tamper-evident and secure package.

Polyolefin shrink film is not biodegradable in the traditional sense, meaning it does not break down naturally over time like organic materials. However, it is recyclable, making it a more eco-friendly option compared to other plastic films such as PVC. The recyclability of POF shrink film allows it to be repurposed into new products, reducing the amount of waste that ends up in landfills.

Eco-Friendly Alternatives to Traditional POF Shrink Film

While traditional POF shrink film is not biodegradable, there are bio-based or compostable alternatives that are specifically designed to break down naturally in the environment. These eco-friendly POF shrink films are made from renewable resources and can decompose over time, offering a more sustainable choice for businesses or consumers who prioritize reducing their environmental impact.

Several factors contribute to the eco-friendly nature of Polyolefin Shrink Film:

Recyclability:

POF shrink film can be recycled into new products, reducing waste and promoting a circular economy. Many recycling facilities accept POF films, making it easier for businesses and consumers to participate in sustainability efforts.

Lower Environmental Impact:

POF shrink film has a smaller environmental footprint than PVC-based shrink films. It does not release harmful chemicals during production or disposal, making it a safer alternative for both human health and the environment.

Energy Efficiency:

The production of Polyolefin shrink film requires less energy compared to other plastic films, resulting in a lower carbon footprint during its manufacturing process.

Non-Toxic and Safe:

POF shrink film is non-toxic and does not release harmful fumes or pollutants when heated. This makes it a safer material for workers and consumers, as well as a better option for packaging food and other consumables.

Polyolefin (POF) shrink filmsoffer superior clarity, strong seals, and the ability to shrink tightly around products, which makes them ideal for packaging in numerous industries. Below is a more detailed guide on the various types of POF shrink films, each designed to meet specific packaging needs.

1. POF Low-Temperature Shrink Film

Description:

The low-temperature shrink film is designed to shrink at lower temperatures, which is essential for packaging heat-sensitive items. This type of film is commonly used in the food industry, particularly for packaging products like chocolate, ice cream, and other temperature-sensitive goods. It provides a secure, protective wrap while preventing heat damage.

Key Features:

Low Shrink Temperature: Shrinks at much lower temperatures compared to standard films.

Ideal for Sensitive Products: Perfect for wrapping products that are easily affected by high heat.

Applications: Food products (chocolate, ice cream, etc.), pharmaceuticals.

2. POF Cross-Linked Shrink Film

Description:

This cross-linked shrink film undergoes a special process that bonds the polymer chains, resulting in a more durable and tear-resistant film. Despite its increased toughness, it maintains excellent shrinkage characteristics, making it ideal for packaging products with complex shapes, such as round or irregular items (e.g., balls, bottled products).

Key Features:

Enhanced Durability: Less likely to tear, providing better protection during handling and transportation.

Strong Shrinkage: Maintains superior shrinkage properties, wrapping products tightly.

Applications: Packaging of spherical products, toys, promotional items, and more.

POF High-Performance Shrink Film

Description:

The high-performance shrink film is designed to be used in high-speed packaging machines. It is highly efficient and reliable, particularly suitable for industries that require fast and high-quality packaging. This type of film is commonly used for semi-finished foods like noodles, baked goods, or even hardware components.

Key Features:

High-Speed Packaging: Works seamlessly with automated packaging lines.

Strong Seals: Provides a tight seal that ensures the product stays protected.

Applications: Semi-finished food products, hardware items, consumer goods.

POF Anti-Fog Shrink Film

Description:

The anti-fog shrink film is specially treated to prevent fogging and condensation from forming on the packaging surface. This feature makes it particularly beneficial for fresh food items such as fruits, vegetables, and meat, where visibility is essential for maintaining product quality and appeal. The film can be used for direct food packaging, maintaining a clear view of the product while enhancing its shelf-life.

Key Features:

Anti-Fogging: Prevents condensation from obscuring product visibility.

Food Protection: Ideal for fresh foods, keeping them visible and attractive.

Applications: Fresh produce, meat products, frozen foods, ready-to-eat meals.

Summary Comparison of POF Shrink Film Types

| Film Type | Shrink Temperature | Durability | Ideal Use |

|---|---|---|---|

| Low-Temperature Shrink Film | Low | Moderate | Heat-sensitive food products |

| Cross-Linked Shrink Film | Medium | High | Irregular-shaped products |

| High-Performance Shrink Film | Standard | High | High-speed packaging applications |

| Anti-Fog Shrink Film | Standard | Moderate | Fresh food products (fruits, meat) |

1. Food Packaging

One of the primary applications of polyolefin shrink film is in the food packaging industry. Its non-toxic nature and ability to maintain a strong barrier against moisture, dirt, and contaminants make it an ideal choice for packaging a variety of food products. POF shrink film helps extend the shelf life of perishable goods while keeping them fresh and visually appealing.

Key Applications in Food Packaging:

Fresh Produce: Vegetables, fruits, and salads are often wrapped in polyolefin shrink film to protect them during transportation and ensure visibility.

Frozen Foods: Frozen meals, pizzas, and snacks are sealed tightly with POF shrink film to prevent freezer burn and maintain freshness.

Bakery Goods: Breads, cakes, and pastries benefit from shrink-wrapped packaging, which protects them from damage while preserving their freshness.

Advantages in Food Packaging:

Moisture and Oxygen Barrier: Helps preserve freshness by keeping moisture in and oxygen out.

High Clarity: Enhances product visibility, allowing consumers to clearly see the item inside.

Non-Toxic and Safe: Polyolefin is food-safe, ensuring that the shrink film is safe for direct contact with edible goods.

2. Consumer Product Packaging

Polyolefin shrink film is extensively used in the packaging of various consumer goods, such as electronics, toys, cosmetics, and household items. The film tightly conforms to the shape of the product, providing secure packaging while maintaining a polished and professional appearance.

Key Applications in Consumer Product Packaging:

Electronics: Phones, tablets, and other electronic gadgets are often shrink-wrapped for protection from dust and moisture during shipping.

Cosmetics: Bottles of shampoo, lotion, and other personal care products benefit from polyolefin shrink film’s ability to provide a tamper-evident seal.

Toys and Games: Polyolefin shrink film is used to package toys and games, protecting them from damage and ensuring they remain intact until purchased.

Advantages in Consumer Product Packaging:

Tamper-Evident: Provides a secure seal that alerts consumers if a product has been opened or tampered with.

Enhanced Protection: Offers a layer of protection against dust, moisture, and handling damage.

Versatile and Customizable: Polyolefin shrink film can be easily customized for different shapes and sizes of products.

3. Pharmaceutical and Medical Packaging

Polyolefin shrink film is also widely used in the pharmaceutical and medical industries, where the safe, secure, and hygienic packaging of products is essential. It ensures that products are protected from contamination and damage while in transit or storage.

Key Applications in Pharmaceutical and Medical Packaging:

Blister Packs: Polyolefin shrink film is used to wrap blister packs of tablets and capsules, keeping them secure and tamper-proof.

Medical Devices: Shrink film is applied to medical equipment, such as syringes, IV bags, and surgical instruments, to maintain sterility.

Vials and Bottles: Polyolefin shrink film is used for packaging liquids, including medications and health supplements.

Advantages in Pharmaceutical and Medical Packaging:

Sterility Preservation: Ensures that medical products remain sterile and safe for use.

Tamper Evident: Provides a clear indication if the packaging has been opened, protecting against counterfeiting.

Safe and Non-Toxic: Polyolefin is non-toxic and suitable for sensitive medical products.

4. Industrial and Hardware Packaging

For heavy-duty applications, polyolefin shrink film provides a strong and protective wrap for industrial goods, hardware, and machinery components. The film offers superior strength, making it ideal for bundling and protecting large or bulky items.

Key Applications in Industrial and Hardware Packaging:

Tools and Equipment: Power tools, hand tools, and machinery parts are wrapped in polyolefin shrink film to prevent rust, dust, and damage.

Construction Materials: Polyolefin is used to wrap bundles of materials like pipes, metal sheets, and tiles, keeping them protected during transport and storage.

Automotive Parts: Car parts and accessories benefit from shrink wrapping to protect them from scratches and environmental damage.

Advantages in Industrial and Hardware Packaging:

Durability: Strong and resistant to punctures, tears, and abrasions, ideal for heavy-duty products.

Weather Resistance: Protects items from the elements during shipping and storage.

Space-Efficient: Shrinks tightly to the product, minimizing packaging volume and improving efficiency.

5. Gift and Promotional Packaging

Polyolefin shrink film is also popular in the gift and promotional product industries. Whether for wrapping holiday gifts, promotional giveaways, or custom packaging, POF shrink film adds a professional touch while ensuring the contents are secure.

Key Applications in Gift and Promotional Packaging:

Gift Baskets: Shrink-wrapped gift baskets keep all items together and provide an attractive, ready-to-gift appearance.

Promotional Items: Companies often use shrink film to package promotional products such as branded merchandise, offering both protection and branding opportunities.

Holiday Gifts: Polyolefin shrink film is widely used for wrapping holiday gift items, creating an eye-catching, glossy finish.

Advantages in Gift and Promotional Packaging:

Aesthetic Appeal: The high clarity and glossy finish make products look more attractive and presentable.

Customizable: Shrink film can be printed with logos or custom designs for branding or personalizing promotional items.

Tamper-Evident: Ensures that gifts or promotional items are intact and unopened before reaching the recipient.

6. Bundling and Group Packaging

Polyolefin shrink film is widely used for bundling multiple items together, providing a cohesive and secure pack. This is especially useful for packaging products that are sold together as a set, such as cans, bottles, or multi-pack items.

Key Applications in Bundling and Group Packaging:

Multi-Pack Items: Drinks, canned goods, and bottles are often bundled together using polyolefin shrink film to provide a secure and neat package.

Retail Displays: Groups of products for retail displays can be tightly wrapped, making them easy to handle and store.

Advantages in Bundling and Group Packaging:

Compact Packaging: Shrink film reduces packaging size, making items easier to store and display.

Protection: Keeps multiple items securely bound together, preventing shifting or damage.

Cost-Effective: Reduces the need for additional packaging materials while offering a secure and attractive bundle.

How Polyolefin (POF) Shrink Films Contribute to Cost-Effective Packaging Solutions

In today's competitive packaging industry, companies are constantly seeking ways to improve efficiency, reduce costs, and enhance the quality of their products. Polyolefin (POF) shrink films have emerged as one of the most cost-effective packaging solutions due to their unique properties, versatility, and ability to reduce overall packaging costs. This article explores how POF shrink films contribute to cost-effective packaging solutions, highlighting their material efficiency, durability, and environmental benefits.

1. Reduced Material Usage and Waste

One of the primary reasons POF shrink films contribute to cost-effective packaging is their ability to reduce material usage while maintaining high-quality performance.

Thin Yet Strong: POF shrink films are thinner than other traditional shrink films such as PVC, yet they retain superior strength and durability. This allows manufacturers to use less material per unit while still providing optimal protection and presentation for the product. By reducing the thickness of the film, manufacturers can cut down on material costs without sacrificing quality.

Minimal Packaging Waste: POF shrink films shrink tightly around products, eliminating the need for excess material. This results in more efficient packaging and less waste, ultimately reducing costs associated with packaging disposal and handling. It also minimizes the storage space required for packaging materials.

2. Enhanced Durability and Protection

POF shrink films offer enhanced protection for a wide range of products, which can help reduce costs related to product damage and returns.

High Tensile Strength: POF shrink films are resistant to punctures, tears, and abrasions, ensuring that products remain intact during transportation, handling, and storage. This durability helps to reduce product loss or damage, which can otherwise lead to costly returns, replacements, and customer dissatisfaction.

Tamper-Evident Features: The tight seal created by POF shrink films makes it difficult for products to be tampered with. This added security reduces the risk of theft, product contamination, or alterations, which could lead to legal liabilities or costly recalls.

Protection from Environmental Factors: POF shrink films shield products from external elements like moisture, dust, dirt, and UV light. This protection helps preserve the quality and shelf-life of the product, particularly in industries like food, cosmetics, and electronics, where product integrity is critical. By minimizing spoilage, manufacturers save money on waste and product degradation.

3. Compatibility with Automated Packaging Systems

POF shrink films are designed to be compatible with both manual and automated shrink-wrapping systems, making them suitable for a wide range of production scales, from small batch runs to high-volume packaging lines.

Faster Packaging Speed: Automated shrink-wrapping machines can quickly and efficiently apply POF shrink films to products, increasing production speed and reducing labor costs. This automation eliminates the need for manual labor and allows for faster turnaround times, ultimately increasing operational efficiency and reducing packaging-related costs.

Higher Throughput: The efficiency of automated systems combined with the reliability of POF shrink films ensures consistent, high-quality packaging at a faster rate. This higher throughput helps companies meet demand more effectively and reduces downtime in the packaging process, contributing to cost savings.

4. Versatility for Multiple Applications

POF shrink films can be used for a wide range of products and packaging formats, making them a versatile option for manufacturers. Their ability to fit various products and packaging requirements contributes to cost savings in several ways.

Multi-Product Packaging: POF shrink films can be used for bundling multiple products together, such as multi-packs of beverages, sets of toys, or other retail bundles. This allows businesses to optimize packaging for bulk or combination sales, potentially increasing sales volume while reducing the overall packaging costs per unit.

Suitability for Different Shapes and Sizes: POF shrink films conform tightly to products of various shapes, sizes, and contours, offering a flexible and efficient packaging solution. Whether packaging irregularly shaped items or small batches, the versatility of POF shrink films reduces the need for multiple packaging solutions, streamlining the process and cutting costs.

5. Energy-Efficient Shrinking Process

The shrinking process for POF shrink films requires less energy compared to other packaging materials, contributing to reduced operational costs.

Lower Shrinking Temperatures: POF shrink films shrink at lower temperatures compared to other shrink films like PVC. This means that the energy consumption during the heat-sealing and shrinking process is significantly reduced. The lower energy requirements help manufacturers save on utility costs, contributing to a more cost-effective packaging operation.

Faster Shrinking Time: POF films also shrink quickly and efficiently, reducing the time needed for the shrink-wrapping process. The shorter time required for the heat application reduces energy consumption and boosts packaging throughput.

6. Cost-Effective Shipping and Storage

POF shrink films not only contribute to savings in the packaging process but also offer significant benefits in terms of shipping and storage.

Lightweight and Compact: POF shrink films are lightweight and take up less storage space compared to other packaging materials. This means companies can store larger quantities of packaging materials in a smaller area, reducing storage costs. Additionally, because POF shrink films are compact, they require less space during transportation, potentially lowering shipping costs.

Efficient Use of Shelf Space: The tight, form-fitting nature of POF shrink films allows for efficient use of shelf space. Products wrapped in POF shrink film require less space on retail shelves compared to those with bulky packaging, which can improve shelf efficiency and reduce the need for additional shelf displays.

7. Sustainability and Environmental Benefits

Sustainability is becoming an increasingly important consideration for businesses and consumers alike. POF shrink films contribute to cost-effective packaging by offering a more sustainable solution compared to many other types of plastic films.

Recyclability: POF shrink films are recyclable in most municipal recycling programs. This helps businesses comply with environmental regulations and meet consumer demand for eco-friendly packaging solutions. By adopting recyclable materials, companies can reduce waste disposal costs and improve their sustainability credentials.

Lower Carbon Footprint: The production of POF shrink films typically requires less energy and produces fewer emissions than other plastic films, such as PVC. By opting for POF shrink films, companies can reduce their carbon footprint and align with environmentally conscious practices while also saving on energy costs.

8. Customization and Branding at No Extra Cost

POF shrink films offer excellent opportunities for customization and branding, which can contribute to cost-effective marketing strategies.

Custom Printing: POF films can be printed with logos, product information, or promotional messages. This customization allows businesses to effectively market their products without the need for additional labeling or packaging materials. By consolidating branding into the shrink film, companies can save on label costs and streamline their packaging process.

Attractive Display with Minimal Effort: The glossy finish of POF shrink films provides a premium, attractive look that enhances the visual appeal of the product. This helps the product stand out on the shelf, attracting more customers and driving sales without the need for costly additional displays or packaging materials.

1. Composition of Polyolefin Shrink Film

Polyolefin shrink film is made from a blend of polyethylene and polypropylene, two types of polymers derived from petroleum. These polymers give the shrink film its flexibility, strength, and excellent shrinkage properties.

Polyethylene (PE): A polymer that provides durability, moisture resistance, and clarity.

Polypropylene (PP): A polymer that offers excellent flexibility and heat shrinkage characteristics.

When combined, these materials form a film that is non-toxic, transparent, and easy to manipulate, making it ideal for packaging and protecting products.

2. The Shrinking Process: Heat Activation

The key to how polyolefin shrink film works lies in its ability to shrink when exposed to heat. The process involves two main stages:

A. Heating the Film

Polyolefin shrink film starts off in a flexible, flat sheet form. When heat is applied—typically through a heat tunnel or heat gun—the polymer molecules in the film begin to move and become more fluid. As the film heats up, its molecules become more active and start to change shape.

B. Shrinking Action

As the film continues to heat up, the molecular structure of the polyolefin material causes it to contract. The film has a built-in memory of a smaller, tightly wound shape. This memory is what makes the film shrink tightly around the product.

Orientation of Molecules: The polymer chains in the film are stretched during manufacturing, which gives the film its ability to shrink. When heat is applied, the chains revert to their original position, pulling the film tight around the object inside.

Degree of Shrinkage: Polyolefin shrink film typically shrinks at a rate of 40-70%, depending on the thickness and the type of film. The shrinking effect is uniform, ensuring that the film fits snugly and evenly around the product.

3. Types of Shrinkage: Directional and Non-Directional

Polyolefin shrink film can undergo two types of shrinkage, each offering different benefits:

A. Directional Shrinkage

In directional shrinkage, the film shrinks more in one direction—either lengthwise or widthwise—than in others. This type of shrinkage allows the film to wrap tightly around specific shapes, making it ideal for irregular or multi-dimensional products.

Uses: Packaging cylindrical items like bottles, cans, or tubes, where the film needs to shrink tightly around the circumference.

B. Non-Directional Shrinkage

In non-directional shrinkage, the film shrinks evenly in all directions. This gives it a uniform, tight fit around the product, making it ideal for packaging items with a symmetrical shape.

Uses: Used for products like boxes, food trays, or other rectangular shapes, ensuring a consistent and secure fit on all sides.

4. Advantages of Polyolefin Shrink Film's Shrinking Ability

The unique shrinking ability of polyolefin shrink film provides several significant advantages for packaging:

A. Tight, Secure Fit

As the film shrinks around the product, it forms a tight and secure seal that protects the item from dust, moisture, dirt, and other contaminants. This ensures that the product remains in pristine condition throughout transport and storage.

Example: For food products like fruits, vegetables, or meats, the shrink film creates an airtight and protective barrier that helps preserve freshness and extend shelf life.

B. Enhanced Aesthetic Appeal

The shrinking process enhances the visual appeal of the product by giving it a smooth, polished appearance. The clear, glossy finish of polyolefin shrink film allows the product to be fully visible, making it more attractive to consumers while also showcasing the quality and design of the item.

Example: For promotional products or retail packaging, the clear, glossy film allows logos, branding, and product details to be visible and easily read.

C. Tamper-Evident Seals

Polyolefin shrink film is often used to create tamper-evident packaging. When the film is applied to a product and heat-shrunk, it creates a sealed barrier that, when broken, clearly shows if the package has been tampered with. This adds an additional layer of security for consumers.

Example: Bottles of shampoo or cosmetics often use shrink-wrapped seals to prevent tampering and ensure product integrity.

5. The Role of Heat in Shaping the Film

Heat plays a crucial role in shaping the polyolefin shrink film and activating its shrinkage properties. The film is typically heated to a temperature range of 120°C to 180°C (250°F to 355°F), depending on the type and thickness of the film being used. The heat causes the polymer molecules to expand and contract, pulling the film tight around the product.

Heat Tunnel: In large-scale packaging operations, heat tunnels are often used to apply the necessary heat to the film. The product passes through the tunnel, and the heat causes the film to shrink around it, forming a tight and protective wrap.

Heat Guns: For smaller-scale or manual packaging processes, heat guns can be used to directly apply heat to the shrink film, shrinking it to fit the product.

6. The Science Behind Polyolefin Shrink Film's Durability

Once the shrink film has conformed tightly to the product, it retains its shape due to the thermoplastic nature of the polyolefin material. This means that even when exposed to environmental factors such as temperature fluctuations, the film will not lose its strength or flexibility.

Strength: Polyolefin shrink film has excellent tensile strength, which ensures it won't tear or puncture easily during transport.

Durability: The film's resistance to environmental conditions such as moisture, dirt, and UV rays makes it ideal for long-term use.

Superior Protection Against Contaminants

One of the most significant advantages of POF shrink films is their ability to provide an airtight, tamper-evident seal. This protective layer shields food from harmful contaminants such as dust, dirt, moisture, and bacteria, which are common risks during handling and transportation.

Moisture Barrier: POF films create a moisture-resistant barrier that helps maintain the freshness of products like meats, cheeses, and baked goods. This ensures the food stays dry and prevents spoilage.

Tamper-Evident Seal: The shrink film's tight wrap creates a seal that is difficult to open without visible damage, providing consumers with confidence that the product has not been tampered with.

2. Extended Shelf Life

By tightly sealing food items in POF shrink film, the freshness and quality of the product are preserved for longer periods. This is particularly important for perishable foods such as fruits, vegetables, and ready-to-eat meals.

Oxygen & UV Barrier: POF shrink films can block oxygen and ultraviolet (UV) light, which are both responsible for causing the degradation of food products. For example, UV light can cause color fading and nutritional loss in fruits and vegetables. The protective barrier of POF shrink film extends the shelf life and keeps food fresh longer.

Reduced Spoilage: The tight shrinkage around food products reduces the chances of air or moisture coming into contact with the food, which can lead to spoilage, mold growth, or freezer burn.

3. Enhanced Aesthetic Appeal

POF shrink films offer excellent clarity and a glossy finish that enhances the presentation of food products. The film’s transparent nature allows consumers to see the product clearly, making it more visually appealing and attractive on store shelves.

Visual Appeal: For products like fresh produce, baked goods, and meats, the clarity of POF shrink films lets the vibrant colors and textures of the food stand out, which can increase consumer interest.

Smooth, Neat Finish: When applied correctly, POF shrink films provide a sleek, smooth surface that showcases the food's shape and quality, improving its overall appearance and making it more desirable for customers.

4. Flexibility for Various Food Products

POF shrink films are incredibly versatile and can be used for a wide range of food items. Their ability to conform to different shapes and sizes makes them ideal for packaging everything from individual snacks to large bundles of fresh produce.

Customization: The shrink film can be easily customized to fit the specific dimensions of the food product. Whether it’s a small candy bar or a large tray of frozen meals, POF films adapt to create the perfect fit.

Multi-Use: In addition to food, POF shrink films can be used for packaging non-food items, such as beverage bottles or mixed product packs, making it an all-in-one solution for various types of food and retail packaging.

5. Environmentally Friendly

In today's packaging industry, sustainability is a key concern, and POF shrink films offer several eco-friendly benefits. While traditionally made from petroleum-based materials, advancements in POF shrink film production have led to more sustainable options.

Recyclability: Polyolefin shrink films are recyclable in most facilities, helping reduce the environmental impact compared to other types of plastic packaging. This makes them a more eco-conscious choice for companies looking to minimize waste.

Reduced Plastic Usage: POF shrink films require a thinner gauge compared to other materials, such as PVC, while still providing the same level of protection and strength. This reduction in material usage contributes to lowering overall plastic consumption.

6. High Heat Resistance

POF shrink films can withstand high temperatures without compromising the integrity of the food or the packaging. This feature makes them suitable for both refrigerated and frozen food items.

Freezer & Microwave Safe: POF shrink films are freezer-safe, meaning they can be used to package frozen foods without the risk of cracking or tearing. Additionally, some POF films are microwave-safe, making it easier for consumers to heat food in its packaging.

Hot Fill Capability: POF shrink films can also handle hot-fill applications, where food products are packaged while still warm. This is commonly used in sauces, soups, and other heat-processed items that require secure and reliable packaging.

7. Cost-Effective Packaging Solution

Polyolefin shrink films provide an affordable packaging solution, especially when compared to other materials like rigid containers or metal cans. The efficiency of shrink wrapping also leads to savings in production time and labor costs.

Lightweight: The lightweight nature of POF shrink films reduces shipping and handling costs, making it an attractive option for companies looking to minimize logistics expenses.

Minimal Waste: POF films are designed to shrink tightly around products, minimizing the amount of excess material. This not only reduces packaging waste but also lowers the cost per unit of production.

8. Quick and Efficient Application

The application of POF shrink films is fast and efficient, particularly when using automated shrink wrapping machines. This reduces production time and increases throughput for manufacturers.

Automatic Machines: Shrink wrapping machines designed for POF films can automatically apply, seal, and shrink the film onto food products, making the process quicker and more consistent.

Streamlined Process: The shrink film process is efficient in terms of time and labor, allowing food manufacturers to package large volumes of products quickly, which is essential for meeting high demand in the food industry.

9. FDA and Food Safety Compliance

Polyolefin shrink films are FDA-approved for direct food contact, meaning they meet the strict regulations for food packaging safety. This is crucial for maintaining the safety and health standards required by the food industry.

Non-Toxic: POF films are free from harmful chemicals such as plasticizers, making them a safe option for food packaging. They are non-toxic and do not leach harmful substances into the food, ensuring the product remains safe for consumption.

Safe for Food Contact: The materials used in POF shrink films comply with food safety regulations, ensuring that the packaging does not pose a risk to consumers.

Superior Aesthetic Appeal

POF shrink films offer excellent clarity and a smooth, glossy finish, making them ideal for retail environments where visual appeal plays a significant role in attracting consumers.

Crystal Clear Packaging: The transparency of POF shrink films allows the product to be clearly visible, making it easier for consumers to assess the quality of the item. For products like toys, electronics, food, and cosmetics, this clarity enhances their presentation and drives purchasing decisions.

Premium Look and Feel: The glossy surface of POF films adds a premium touch to retail packaging, elevating the perceived value of the product. It provides an attractive, high-end appearance that catches the eye of consumers in a competitive retail setting.

2. Enhanced Protection and Durability

One of the primary reasons for using POF shrink films in retail packaging is their ability to protect products from damage during transportation, handling, and storage.

Tamper-Evident Packaging: POF shrink films are designed to create a tight, tamper-evident seal that prevents unauthorized access to the product. This provides consumers with confidence that the product has not been altered, making it more trustworthy and safe to purchase.

Resistance to Tears and Punctures: POF shrink films are more durable than many other types of shrink films, with high tensile strength that makes them resistant to tears, punctures, and abrasions. This ensures that the product remains intact and protected throughout its journey from manufacturer to retailer.

Protection from Environmental Factors: POF shrink films offer protection against environmental factors such as moisture, dust, and dirt. By keeping the product clean and dry, they preserve the product’s quality and integrity, reducing the chances of spoilage or degradation.

3. Versatility for a Wide Range of Products

POF shrink films are highly versatile and can be used for a wide variety of retail products. They conform easily to products of different shapes and sizes, providing a flexible packaging solution for almost any item.

Perfect Fit for Odd Shapes: Whether you're packaging cylindrical bottles, irregularly shaped products, or stacked goods, POF shrink films mold tightly around the contours of the product, providing a perfect fit. This makes them ideal for items that require a custom-fit or need a snug, secure wrap.

Multi-Product Packaging: POF shrink films can be used for bundling multiple items together, such as multi-packs of beverages, sets of toys, or retail gift bundles. This allows for cost-effective and efficient packaging that maximizes shelf space and enhances the appeal of combined product offerings.

4. Cost-Effective Packaging Solution

POF shrink films offer a highly cost-effective solution for retail packaging. Their affordability and ease of use make them an attractive choice for businesses looking to streamline packaging operations without compromising on quality.

Thin Yet Strong: POF shrink films are thinner than other plastic films, yet they retain their strength and durability. This reduces material costs while still providing the necessary protection for the product.

Reduced Packaging Waste: POF shrink films are highly efficient in terms of material usage. The film shrinks tightly around the product, reducing excess packaging material and minimizing waste. This not only helps to lower costs but also contributes to more sustainable packaging practices.

Efficiency in Packaging: The ease of use of POF shrink films allows for quick and efficient packaging processes, whether done manually or with automated shrink wrap machines. This reduces labor costs and increases production efficiency.

5. Environmentally Friendly Options

As consumer demand for eco-friendly packaging continues to rise, POF shrink films offer a more sustainable alternative to other materials like PVC or non-recyclable plastics.

Recyclability: POF shrink films are recyclable in most municipal recycling programs, helping to reduce the environmental impact associated with packaging waste. Many companies are now opting for POF films as part of their broader sustainability initiatives.

Lower Carbon Footprint: The production of POF shrink films typically requires less energy than the production of other types of plastic films, contributing to a lower carbon footprint in the manufacturing process.

6. Compatibility with Automated Packaging Systems

POF shrink films are compatible with a wide range of automated shrink wrapping systems, which makes them highly efficient for large-scale retail packaging operations.

Automated Shrink Wrapping: For high-volume packaging, POF shrink films can be applied using automated machines that quickly seal and shrink-wrap products in a controlled manner. This streamlines the packaging process, improving consistency and reducing the time spent on each product.

Consistency and Precision: Automated systems ensure that each product is packaged precisely, with a consistent application of shrink film. This helps to maintain a professional, uniform appearance across all units, contributing to an organized and aesthetically pleasing retail display.

7. Consumer Convenience

POF shrink films offer convenience not only for manufacturers and retailers but also for consumers.

Easy to Open: POF shrink films are designed to be easy to open without the need for additional tools. This makes the packaging consumer-friendly, allowing buyers to quickly access the product once purchased.

Portability and Lightweight: POF shrink films are lightweight and flexible, making the packaged products easy to handle and transport. This is particularly important for retail items that need to be carried home by consumers, such as packaged foods, cosmetics, or small electronic devices.

8. Compliance with Regulatory Standards

Retail products are often subject to specific packaging and labeling regulations. POF shrink films are FDA-approved for direct food contact and meet various other industry standards, ensuring that they comply with legal and safety requirements.

Food Safety Compliance: POF shrink films are non-toxic and free from harmful chemicals, making them a safe choice for food packaging. They also meet FDA regulations for packaging products that come into direct contact with food.

Tamper-Proof Features: In many regions, packaging must include tamper-evident features. POF shrink films naturally provide this function, ensuring compliance with product safety regulations and helping to protect consumers.

9. Flexibility for Branding and Marketing

POF shrink films can be easily customized with branding and marketing messages, offering opportunities to enhance the product's appeal through print designs.

Custom Printing: POF shrink films can be printed with logos, product information, or promotional messages. This customization helps brands increase visibility and strengthen consumer recognition in a competitive retail environment.

Attractive Shelf Presence: The glossy finish and clarity of POF shrink films enhance the look of any product, making it stand out on retail shelves and appealing to customers.

Polyolefin (POF) and PVC shrink films are both widely used in packaging, but they have distinct characteristics that make them suitable for different applications. Below is a comparison of the two based on key factors such as material properties, performance, and applications:

| Feature | Polyolefin Shrink Film (POF) | PVC Shrink Film |

|---|---|---|

| Material Composition | Made from non-toxic, environmentally friendly polymers like polyethylene and polypropylene. | Made from polyvinyl chloride (PVC), a more rigid plastic material. |

| Shrinkage | Exhibits uniform shrinkage at a lower temperature range (typically 70°C to 110°C). | Shrinks at a higher temperature, typically around 120°C to 180°C. |

| Strength & Durability | Stronger and more tear-resistant; suitable for packaging heavier items. | Less durable and prone to tearing, but offers a tight and firm shrink. |

| Clarity | Offers high clarity and gloss, making it ideal for display packaging. | Provides good clarity but may not be as shiny or glossy as POF. |

| Environmental Impact | More environmentally friendly, as POF is recyclable and less harmful to the environment. | PVC is less eco-friendly and more difficult to recycle. |

| Applications | Commonly used for food packaging, cosmetics, and electronics due to its non-toxic properties. | Often used for industrial packaging and non-food products, where high shrinkage is needed. |

| Cost | Slightly higher in cost due to better performance and eco-friendliness. | Typically less expensive than POF. |

| Flexibility | More flexible and can stretch more easily without tearing. | Less flexible and more rigid, which can limit its applications in some cases. |

| Resistance to Conditions | Resistant to punctures and tearing, making it ideal for packaging irregularly shaped objects. | More vulnerable to punctures and damage, especially during handling. |

Summary of Differences

Material Composition: POF is made from non-toxic and recyclable materials, while PVC is made from more rigid plastic, making POF the more eco-friendly choice.

Shrinkage and Temperature: POF shrinks at lower temperatures, making it suitable for products sensitive to heat, whereas PVC requires higher temperatures to shrink, often resulting in higher energy consumption.

Durability and Strength: POF is stronger and more resistant to tearing, which makes it ideal for packaging a wider range of products, including heavier or irregularly shaped items.

Applications: POF is commonly used in food packaging and products that require high clarity and a clean, attractive appearance. PVC is often used for industrial applications or where high shrinkage is a priority.

Cost: POF is generally more expensive due to its better properties and environmental benefits, while PVC is less costly but comes with some environmental trade-offs.

Polyolefin (POF) shrink films are widely used in various packaging applications due to their excellent performance and versatility. However, choosing the right type of POF shrink film for your specific needs requires careful consideration of several factors. Below are key elements to consider when selecting the ideal POF shrink film for your packaging requirements.

1. Shrinkage Properties

The shrinkage of POF films is one of the most important factors to consider, as it impacts the final appe

| Factor | Considerations |

|---|---|

| Uniform Shrinkage | POF films typically offer uniform shrinkage, which ensures the film shrinks evenly around the product. |

| Temperature Range | POF films shrink at lower temperatures compared to other materials. Typically, POF shrinks effectively at temperatures between 70°C and 110°C. |

| Shrink Ratio | Ensure that the film provides an appropriate shrink ratio for the shape and size of your product. Typically, a 2:1 or 3:1 shrink ratio is common. |

Film Clarity and Aesthetic Appeal

The clarity of the film plays an important role in ensuring that the product inside the packaging is clearly visible and appealing to consumers.

| Factor | Considerations |

|---|---|

| Transparency | POF films offer excellent clarity, allowing the product to be seen clearly through the film. |

| Gloss | POF films are glossy and help enhance the visual appeal of the packaging, making it look more premium. |

| Printing Surface | POF films provide a smooth surface for printing, allowing for high-quality graphics and branding on the packaging. |

Strength and Durability

The strength of the shrink film is vital for ensuring the packaging can withstand handling, transportation, and storage without tearing or puncturing.

| Factor | Considerations |

|---|---|

| Tensile Strength | POF films have high tensile strength, which prevents tearing and ensures the film maintains its integrity during packaging and distribution. |

| Tear Resistance | POF films are known for their high resistance to tearing, which is particularly important when handling sharp or irregularly shaped products. |

| Impact Resistance | POF films have strong impact resistance, making them ideal for fragile or sensitive products like electronics or food items. |

Environmental Impact

With increasing concern for environmental sustainability, the ecological impact of packaging materials is an important consideration.

| Factor | Considerations |

|---|---|

| Recyclability | POF films are recyclable, making them an eco-friendly alternative to materials like PVC that are more difficult to recycle. |

| Non-Toxic | POF films are non-toxic and do not release harmful chemicals, making them safer for food and sensitive products. |

| Biodegradability | While not fully biodegradable, POF films are more environmentally friendly compared to many other types of shrink films. |

When selecting a shrink film, the cost of the material is always an important consideration, especially if you're working with tight budgets.

| Factor | Considerations |

|---|---|

| Material Cost | POF films tend to be more expensive than PVC films, but their superior performance, strength, and eco-friendliness often justify the higher cost. |

| Production Efficiency | POF films shrink at lower temperatures, which can reduce energy consumption and improve overall packaging efficiency. |

| Bulk Purchase Discounts | Bulk purchases of POF shrink films may offer significant cost savings, making it more affordable for high-volume manufacturers. |

Application Type

Different types of products require different levels of protection and film characteristics. Understanding your product's needs is crucial.

| Factor | Considerations |

|---|---|

| Food Packaging | POF films are widely used in food packaging due to their non-toxic properties and ability to maintain freshness. |

| Retail Packaging | POF films' clarity and ability to tightly conform to products make them ideal for retail packaging, ensuring a sleek and appealing look. |

| Industrial Packaging | For heavy-duty or bulky items, choose a POF film with higher tensile strength to withstand rough handling and transportation. |

Sealability

The ability to effectively seal the film is crucial to maintaining the integrity of the packaged product.

| Factor | Considerations |

|---|---|

| Heat Seal Strength | POF films have excellent heat-sealing properties, which ensures that the packaging stays securely closed without leakage. |

| Seal Width | Choose POF films that provide an appropriate seal width for your specific packaging machine and product type. |

| Sealing Temperature | Ensure that the POF film can be sealed at the temperature of your packaging process without compromising its integrity. |

Summary of Key Factors to Consider

| Factor | Importance |

|---|---|

| Shrinkage | Ensures the film conforms tightly to the product, providing a sleek, professional look. |

| Clarity & Aesthetic | Enhances product visibility and appeal for retail and consumer-facing products. |

| Strength & Durability | Critical for protecting products during transportation, handling, and storage. |

| Environmental Impact | Choosing recyclable and non-toxic films contributes to sustainability goals. |

| Cost Efficiency | Balances material cost with performance and energy savings. |

| Application Type | Ensures the film is suitable for the specific packaging needs of your product (e.g., food, electronics). |

| Sealability | Ensures a secure and reliable package for product integrity and freshness. |

Polyolefin (POF) shrink films have been a staple in the packaging industry for many years, thanks to their versatility, eco-friendly properties, and strong performance. As the packaging landscape continues to evolve, several key trends and innovations are shaping the future of POF shrink films. In this article, we will explore these trends, the ongoing innovations, and how they are expected to transform the packaging industry in the coming years.

1. Eco-Friendly and Sustainable Solutions

With increasing global focus on sustainability, the demand for environmentally friendly packaging solutions is rising. Polyolefin films are gaining significant attention due to their recyclable nature and non-toxic properties.

Biodegradable Additives: Innovations in biodegradable additives are helping POF films become more eco-friendly without compromising their performance.

Recycling Initiatives: POF films are easier to recycle compared to PVC shrink films, and manufacturers are investing in technology to make recycling more efficient.

As consumers and businesses alike become more eco-conscious, the demand for sustainable packaging solutions is expected to continue driving the adoption of POF shrink films.

2. Increased Clarity and Aesthetics

Consumer products, particularly in the food and retail sectors, rely on attractive packaging that enhances product appeal. The future of POF films is leaning towards even higher clarity, better gloss, and improved transparency.

Crystal Clear Films: POF films are being engineered to offer superior transparency, allowing products to shine through with minimal distortion.

Advanced Printing Capabilities: As brands look to enhance their identity, there's a growing emphasis on printing technologies that allow for high-definition, vibrant prints on POF films.

These advancements in clarity and printing techniques are set to elevate the consumer experience, making POF shrink films a popular choice for premium product packaging.

3. Enhanced Strength and Durability

Packaging that is both protective and visually appealing is essential, especially for fragile or high-value products. One key trend in POF shrink film development is the enhancement of film strength and durability.

Improved Tear and Puncture Resistance: Manufacturers are focusing on enhancing the tear resistance of POF films to ensure they perform well even with irregularly shaped or sharp-edged products.

Higher Tensile Strength: Future POF films are expected to offer higher tensile strength, which will help prevent packaging from breaking under pressure or during transport.

These innovations ensure that POF films are more robust, providing better protection for products and reducing the risk of damage during handling and shipping.

4. Cost Efficiency and Performance Optimization

With companies constantly looking for ways to reduce costs while maintaining high-quality packaging, the future of POF shrink films is expected to offer enhanced performance at competitive prices.

Optimized Production Processes: Manufacturers are continually working on refining the production process of POF films, improving efficiency and reducing waste. This will help bring down the cost of POF shrink films, making them more accessible to a wider range of businesses.

Lower Energy Consumption: POF films are known for their ability to shrink at lower temperatures, and innovations in film technology will likely reduce energy consumption further, leading to more cost-effective and environmentally friendly production methods.

This focus on cost efficiency ensures that businesses can use high-quality POF shrink films without exceeding their packaging budgets.

5. Customizable Film Solutions

Customization is a growing trend in the packaging industry. The demand for tailored packaging solutions is increasing as brands aim to offer unique packaging experiences to their customers.

Tailored Shrink Profiles: Manufacturers are working on offering shrink films with customizable shrink profiles, allowing them to better conform to various product shapes and sizes.

Color and Texture Customization: There's also a rising demand for POF films that offer specific colors and textures, which can be crucial for product branding and differentiation.

As custom solutions become more accessible, POF films will be able to meet the exact packaging needs of businesses across different industries.

6. Automation and Smart Packaging Integration

The packaging industry is increasingly integrating smart technology into the manufacturing and distribution processes, and POF films are no exception.

Automated Packaging Lines: With the rise of automated packaging systems, POF shrink films are being optimized for high-speed packaging lines. These films need to maintain consistent quality and performance to meet the demands of fast-paced production environments.

Smart Packaging Features: Smart features such as RFID tags and QR codes are becoming more common in product packaging. POF films can be adapted to accommodate these features, adding value to the consumer experience.

At Zhejiang Jiuteng Packaging Co., Ltd., our Polyolefin (POF) Shrink Films and Cross-Linked Shrink Films are known for their performance and premium quality. Here's what makes our films stand out:

1. Optimized Performance

We offer a range of POF shrink films in various gauges, from thin to thick, ensuring reliable results for any packaging need.

2. Exceptional Clarity and Gloss

Our films provide market-leading clarity and a consistent gloss, showcasing products with a premium finish.

3. Customizable Solutions

With customizable widths and options like opaque, low shrink force, and high-speed films, we offer tailored solutions to fit your specific packaging requirements.

4. Innovative Features

We also provide Hotslip, Pre-perforation, and Print Treatment options for enhanced performance and customization.

Jiuteng's Polyolefin Shrink Films combine high quality, customization, and innovative features, offering the perfect solution for your packaging needs.