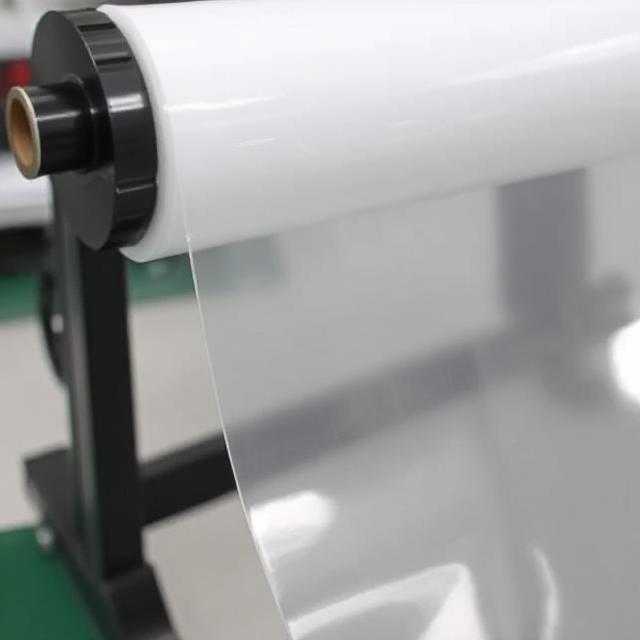

PE (Polyethylene) shrink film is a type of thermoplastic material that shrinks when heat is applied. It is widely used for packaging purposes due to its ability to conform tightly around products, providing a secure and protective wrap. The film is made from polyethylene, a versatile plastic known for its strength, flexibility, and cost-effectiveness. When heated, the material shrinks in all directions, tightly adhering to the surface of the item it is covering, creating a durable, tamper-evident seal.

Polyethylene (PE) shrink film is widely recognized for its excellent heat shrinkage performance, making it one of the most commonly used materials in the packaging industry. The film’s ability to shrink uniformly and tightly around products when exposed to heat ensures both protection and an attractive presentation. This shrinkage capability is a key factor that determines its widespread use across various sectors.

Heat Shrinkage Performance of PE Shrink Film

The shrinkage of PE shrink film is a result of its thermoplastic nature. When the film is heated, the polymer chains in the material contract, causing the film to shrink tightly around the object it is wrapping. This process is highly dependent on several factors, including the type of polyethylene used, the thickness of the film, the temperature at which it is heated, and the duration of heating.

Key Performance Characteristics:

High Shrinkage Rate: PE shrink film can shrink up to 60-70% in both length and width, providing a tight, secure fit around a variety of products.

Uniform Shrinkage: When exposed to heat, the film shrinks evenly, ensuring that the product is consistently wrapped without wrinkles or air pockets. This uniformity is particularly important for products that require an aesthetically pleasing appearance.

Temperature Sensitivity: The heat required for PE shrink film to shrink varies depending on the film thickness and its formulation. Typically, PE shrink films require heating temperatures between 120°C to 160°C (248°F to 320°F) to activate the shrinkage process.

Strength and Durability: Once shrunk, the PE film forms a strong protective layer around the product. This provides resistance to punctures, moisture, dust, and other environmental factors. The material remains flexible, ensuring it can adapt to a wide range of product shapes and sizes without cracking.

Factors Affecting Heat Shrinkage Performance

Film Thickness: Thicker PE films tend to shrink less compared to thinner films. The shrinkage rate is also affected by the film’s composition, with certain additives enhancing the shrinkage properties.

Temperature Control: Accurate control of heating temperature is crucial for optimal shrinkage performance. Too high a temperature can cause over-shrinkage or even damage to the product, while too low a temperature may result in incomplete shrinkage.

Time of Exposure: The time the film is exposed to heat also plays a role in its shrinkage performance. Prolonged exposure can cause the film to shrink too much, leading to deformation of the product or the film itself.

Type of Product: The nature of the product being wrapped impacts how well the PE film performs. Irregularly shaped or delicate products may require more careful handling during the shrinkage process to avoid damage.

The heat shrinkage properties of PE shrink film make it ideal for a variety of packaging applications across multiple industries. Some of the key applications include:

1. Food and Beverage Packaging

PE shrink film is commonly used for packaging food and beverages, where it provides a secure seal that helps maintain freshness and hygiene. The film shrinks tightly around bottles, cans, and multi-pack configurations, providing a tamper-evident seal that assures consumers of product safety. The clarity of PE shrink film also allows consumers to easily view the contents of the packaging, which is essential for food and beverage products.

Multi-Pack Packaging: PE shrink film is ideal for wrapping multi-packs of bottles, cans, or other consumable goods. It ensures the product stays together during transportation while also improving shelf appeal.

Protection from Contamination: The shrink film forms a tight barrier against dust, moisture, and contaminants, keeping the food product safe and extending its shelf life.

2. Retail and Consumer Goods

In the retail sector, PE shrink film is widely used for wrapping consumer goods such as electronics, toys, and household items. The film provides a neat, professional look that enhances product presentation on shelves while offering protection from scratches and damage. Additionally, it can be used to wrap multiple items together in a bundle, improving handling and transport.

Tamper-Evident Packaging: Shrink film offers the advantage of being tamper-evident, ensuring that the product is not altered before purchase.

Branding and Customization: The film can be printed with logos, product information, and marketing messages, allowing brands to promote their products effectively.

3. Pharmaceuticals and Medical Packaging

PE shrink film is an excellent choice for packaging pharmaceutical products, medical devices, and over-the-counter medications. Its ability to create a secure, tamper-proof seal is essential in ensuring product integrity and safety. The film is also ideal for wrapping items like pill bottles, medical kits, and diagnostic tools, protecting them from contamination and environmental exposure.

Tamper-Evident Seals: PE shrink film offers a reliable solution for creating tamper-proof packaging, ensuring that consumers can be confident in the safety of their products.

Sterility Maintenance: For medical devices and pharmaceuticals, the film provides a clean, sterile barrier to protect the contents from dirt or moisture.

4. Industrial Packaging

PE shrink film is used in various industrial applications to wrap machinery, components, and large equipment. It offers robust protection during storage and transportation, ensuring that items are kept free from dust, dirt, and moisture. Its stretchability and durability make it suitable for heavy-duty applications.

Heavy-Duty Protection: The film is ideal for bundling large or bulky items together, preventing shifting during transportation while offering robust protection.

Weatherproofing: The moisture-resistant properties of PE shrink film make it ideal for use in outdoor storage or shipping, protecting products from rain, humidity, and dust.

5. Cosmetics and Personal Care Packaging

PE shrink film is also used to wrap personal care products, including bottles of shampoo, lotions, and cosmetics. It provides an attractive and secure packaging solution that protects the products from contamination and tampering while maintaining their aesthetic appeal on store shelves.

Shelf Appeal: The high clarity of PE shrink film enhances the visual appeal of cosmetic packaging, making products more attractive to consumers.

Security and Protection: The film forms a strong protective barrier against dirt, damage, and tampering, ensuring that products remain in pristine condition.

Here's a table summarizing the Applications of PE Shrink Film based on the previous content:

| Industry/Use | Application | Benefits |

|---|---|---|

| Food and Beverage Packaging | Wrapping bottles, cans, and multi-packs. | Tamper-evident seal, freshness, moisture protection, extended shelf life. |

| Retail and Consumer Goods | Wrapping consumer goods like electronics, toys, and household items. | Neat presentation, protection from scratches, multi-item bundling. |

| Pharmaceuticals & Medical | Packaging pharmaceutical products, medical devices, and medications. | Tamper-evident, sterile protection, safety assurance. |

| Industrial Packaging | Wrapping machinery, components, and heavy-duty equipment. | Protection from dust, dirt, and moisture, ideal for transport/storage. |

| Cosmetics & Personal Care | Wrapping bottles of lotions, shampoos, cosmetics, and personal care products. | Enhanced shelf appeal, tamper-evident, protection from contamination. |

Polyethylene (PE) shrink film is a highly versatile material that comes in various types, each designed to meet specific requirements depending on the product being packaged, the desired performance, and environmental considerations. Understanding the different types of PE shrink film can help businesses choose the right solution for their packaging needs. Below are the most common types of PE shrink film and their characteristics:

1. Low-Density Polyethylene (LDPE) Shrink Film

LDPE is one of the most commonly used types of PE shrink film. It has a low density, which gives it a flexible and stretchable nature. LDPE shrink film is highly adaptable and can be used for a wide range of products.

Key Features:

Flexibility: LDPE shrink film is highly flexible, making it ideal for wrapping irregularly shaped items.

High Shrinkage Rate: It has a good shrinkage rate, which allows the film to fit tightly around the product.

Soft Texture: The film is soft to the touch, making it suitable for delicate or sensitive products.

Low Cost: LDPE is generally more affordable compared to other PE films, making it a cost-effective solution for many applications.

Applications:

Food packaging (e.g., bakery items, fresh produce)

Retail packaging (e.g., toys, electronics)

Industrial packaging for lightweight products

2. Linear Low-Density Polyethylene (LLDPE) Shrink Film

LLDPE shrink film is a stronger and more durable variant of LDPE. It is made using a different polymerization process, which results in a more uniform molecular structure and enhanced performance characteristics.

Key Features:

Higher Strength: LLDPE is stronger than LDPE and has greater tear and puncture resistance, making it ideal for heavier items.

Excellent Clarity: LLDPE provides high transparency, ensuring product visibility.

Stretchability: This type of shrink film offers excellent stretchability, allowing it to shrink tightly and conform to the shape of the product.

Good Impact Resistance: LLDPE shrink film is known for its ability to withstand rough handling during transportation.

Applications:

Packaging of heavier and bulkier items (e.g., bottled beverages, multi-packs)

Protective packaging for products that require durability and flexibility

Industrial applications where high strength is needed

3. High-Density Polyethylene (HDPE) Shrink Film

HDPE shrink film has a higher density than both LDPE and LLDPE, giving it a more rigid structure and making it less flexible. While it’s less commonly used for shrink wrapping products, it offers excellent strength and barrier properties.

Key Features:

Rigid and Strong: HDPE is stiffer and stronger, providing better protection for heavy-duty applications.

Superior Barrier Properties: HDPE offers better resistance to moisture and gases compared to LDPE and LLDPE.

Lower Shrinkage: It has a lower shrinkage rate than LDPE and LLDPE, which may make it less suitable for wrapping products with intricate shapes.

Costlier: HDPE tends to be more expensive than other types of PE films, especially for applications where high flexibility is needed.

Applications:

Industrial packaging for heavy-duty equipment and machinery

Packaging requiring high moisture resistance, such as chemicals and oils

Products needing stronger barrier properties

4. Medium-Density Polyethylene (MDPE) Shrink Film

MDPE shrink film is a compromise between LDPE and HDPE, offering a balance of flexibility and strength. It is commonly used for applications where both durability and elasticity are needed.

Key Features:

Balanced Flexibility and Strength: MDPE provides a good balance between the flexibility of LDPE and the strength of HDPE.

Impact and Puncture Resistance: It is resistant to punctures and tears, making it suitable for both light and medium-duty products.

Moderate Shrinkage: MDPE shrink film offers moderate shrinkage, which makes it suitable for a wide range of products.

Applications:

Packaging of medium-duty products, such as hardware or non-perishable food items

Industrial products requiring moderate strength and flexibility

Protective wrapping for products sensitive to moisture

5. PE Co-Extruded Shrink Film

Co-extruded PE shrink film is made by combining two or more layers of different polyethylene materials, typically LDPE, LLDPE, and sometimes HDPE. This type of film offers enhanced performance by combining the properties of various materials.

Key Features:

Multi-Layered Protection: Co-extruded films provide the benefits of multiple polyethylene types in one film. For example, the outer layer may provide high clarity and impact resistance, while the inner layer offers sealing properties.

Enhanced Barrier Properties: The co-extruded film provides better protection against external factors such as moisture, dust, and contaminants.

Superior Shrinkage Control: The combination of layers allows for better control over the shrinkage process, ensuring a tight and secure wrap.

Applications:

Packaging of high-value products that require enhanced protection, such as electronics or premium goods

Food packaging requiring superior moisture and contamination resistance

Large or irregularly shaped products that need uniform shrinkage

6. Colored PE Shrink Film

Colored PE shrink film is a variation of the standard film, available in various colors. It is primarily used for marketing, branding, and differentiation purposes.

Key Features:

Aesthetic Appeal: The color options allow for customized branding, product differentiation, and aesthetic appeal on the shelf.

Privacy and Protection: In some cases, colored shrink film provides additional privacy or protection for the contents by concealing the product inside.

Visibility: While it is less transparent than clear shrink films, it can still be used to protect products while offering an attractive design.

Applications:

Product packaging for marketing and promotional items

Seasonal packaging (e.g., for holidays or special events)

Packaging of items requiring privacy or confidentiality, such as gifts or certain industrial products

Polyethylene (PE) shrink film offers numerous benefits that make it an ideal choice for a wide range of packaging applications. Whether used for food, beverage, retail, or industrial packaging, PE shrink film provides a reliable, cost-effective, and versatile solution. Below are some of the key advantages of PE shrink film:

1. Cost-Effectiveness

PE shrink film is one of the most affordable packaging materials available. The production process for PE is less expensive compared to other types of shrink films like PVC or POF. This makes PE shrink film an excellent option for businesses looking to minimize packaging costs without sacrificing quality.

Lower Material Costs: PE film is generally more cost-effective than other materials like PVC or POF, making it suitable for high-volume packaging operations.

Affordable Shrink Wrapping Machines: PE shrink film can be used with a variety of shrink wrapping machines that are also budget-friendly, making it accessible for businesses of all sizes.

2. High Transparency and Product Visibility

One of the standout features of PE shrink film is its high clarity, which makes it an ideal choice for retail and consumer packaging. The transparency of the film allows the product to be clearly visible, enhancing its appeal on store shelves.

Enhanced Brand Visibility: The clear film provides excellent product visibility, which is crucial for branding and marketing. Consumers can see the product without having to open the packaging.

Aesthetic Appeal: The high gloss and smooth surface of PE shrink film make it aesthetically appealing, attracting consumers’ attention in retail environments.

3. Durability and Protection

PE shrink film provides strong protection for products, safeguarding them from external factors such as moisture, dust, dirt, and physical damage. Once the film shrinks around the product, it forms a tight, secure seal, ensuring that the item remains intact throughout handling, transportation, and storage.

Moisture and Dust Resistance: The film provides a barrier against water, dust, and dirt, making it particularly beneficial for products that are sensitive to these environmental factors.

Puncture and Tear Resistance: PE shrink film offers excellent resistance to punctures, tears, and abrasions, ensuring that the packaging remains intact even in rough handling conditions.

4. Tamper-Evident Packaging

PE shrink film provides a tamper-evident solution, offering consumers confidence in the safety and integrity of the product. The shrink-wrapped film is difficult to remove or alter without leaving visible signs of tampering, making it an effective deterrent against theft or contamination.

Enhanced Product Security: The shrink film adheres tightly to the product, making it difficult to tamper with, thereby improving security during storage, shipping, and display.

Consumer Confidence: Tamper-evident packaging is important in industries like food and pharmaceuticals, where product integrity is paramount.

5. Versatility

PE shrink film is highly versatile and can be used for a wide range of applications, from packaging individual products to bundling multiple items together. It can be used to wrap products of various shapes and sizes, making it ideal for both small and large packaging requirements.

Customizable Applications: PE shrink film can be tailored to fit any product, whether it’s a single item, a multi-pack, or a large industrial product.

Suitability for Different Industries: It is used in food packaging, beverage packaging, retail, electronics, pharmaceuticals, and industrial sectors, demonstrating its broad versatility.

6. Environmental Benefits

PE shrink film is considered to be more environmentally friendly compared to other types of plastic films like PVC. Polyethylene is a recyclable material, making PE shrink film a more sustainable option for businesses aiming to reduce their environmental impact.

Recyclable: PE shrink film can be recycled after use, reducing the amount of waste in landfills and promoting a circular economy.

Lower Carbon Footprint: The production of PE shrink film typically results in lower carbon emissions compared to other types of shrink films, making it a more eco-friendly choice for packaging.

7. Easy to Use and Process

PE shrink film is easy to handle and can be processed quickly using shrink wrapping machines. The film’s high shrinkage rate ensures that it tightly conforms to the shape of the product, providing an excellent seal without the need for complex techniques.

Fast Shrinkage: PE shrink film shrinks quickly when exposed to heat, allowing for high-speed packaging operations, which is essential in mass production.

Compatible with Standard Equipment: PE shrink film works with a variety of shrink wrapping machines, including manual, semi-automatic, and fully automatic systems.

8. Customization Options

PE shrink film offers a wide range of customization options, allowing businesses to create packaging that aligns with their brand identity and product needs. The film can be printed with logos, product information, and other designs, making it a powerful marketing tool.

Custom Printing: PE shrink film can be printed with high-quality graphics, text, and logos, helping brands to create eye-catching packaging that stands out on the shelf.

Variety of Finishes: The film can be produced with different finishes, including glossy, matte, and clear, depending on the desired aesthetic and functionality.

9. Safe for Food Packaging

PE shrink film is safe for food packaging and is widely used in the food and beverage industry. The material is non-toxic and complies with food safety standards, ensuring that it does not contaminate the product inside.

Food-Safe Material: PE is considered safe for direct contact with food products, making it a reliable option for packaging edible items like fruits, vegetables, and baked goods.

Hygienic: The film provides a clean, protective barrier that helps maintain the hygiene and freshness of food products.

Polyethylene (PE) shrink film is a popular packaging material due to its ability to conform tightly around products, offering a secure and protective wrap. Understanding how PE shrink film works is essential for industries seeking to optimize packaging processes and ensure product protection. The process involves a combination of heat, material properties, and the product shape, which results in the film shrinking around the item and forming a tight, durable seal.

1. The Shrinkage Process

PE shrink film functions through a thermoplastic process, meaning it is a material that becomes pliable when heated and solidifies again when cooled. The basic principle behind how PE shrink film works is the material’s ability to shrink when exposed to heat. Here's a step-by-step breakdown of the process:

Step 1: Wrapping the Product

The PE shrink film is wrapped around the product to be packaged. The film is generally pre-manufactured in rolls, allowing it to be easily cut to the desired size and shape. When wrapping the product, the film may slightly overlap, creating a seam where the ends of the film meet.

Step 2: Sealing the Edges

Once the product is wrapped in the film, the edges of the PE shrink film are typically sealed using a heat sealer. The sealer applies heat and pressure to fuse the edges of the film together, forming a closed package. This step ensures that the film remains securely in place during the shrinking process.

Step 3: Heating the Film

The wrapped product with sealed edges is then exposed to heat. This can be done using a variety of heat sources, such as a heat tunnel, shrink oven, or infrared heat system. As the PE shrink film is heated, it begins to soften and shrink. The film’s polymer chains, which are originally in an unorganized state, realign and contract when exposed to heat.

Temperature: PE shrink films typically require a temperature range of 120°C to 160°C (248°F to 320°F) to initiate the shrinkage process. The exact temperature will depend on the thickness of the film and the product being wrapped.

Uniform Shrinkage: When the film reaches the right temperature, it shrinks uniformly in both length and width, closely conforming to the shape of the product inside.

Step 4: Cooling and Solidifying

Once the PE shrink film has shrunk tightly around the product, the package is cooled down. The cooling process solidifies the film, locking it in place and ensuring that it stays tightly wrapped. As the film cools, it contracts further, becoming firm and providing a strong protective seal around the product.

Instant Solidification: The cooling process happens quickly, ensuring that the film retains its shape without any distortion or slack.

Shrink films are commonly used for packaging various products across multiple industries due to their ability to shrink tightly around an object when exposed to heat. Polyethylene (PE) shrink film, in particular, is a widely used material, but it competes with other shrink films, such as Polyvinyl Chloride (PVC) and Polyolefin (POF) films. Understanding the differences between PE shrink film and other shrink films is crucial for businesses that want to select the best packaging solution based on cost, performance, and environmental considerations.

1. Polyethylene (PE) Shrink Film

PE shrink film is a popular and versatile option for packaging, especially for products in retail, food, and industrial sectors. It is made from polyethylene, a thermoplastic polymer that shrinks when exposed to heat.

Key Characteristics of PE Shrink Film:

Material: Made from polyethylene (low-density or linear low-density polyethylene).

Cost-Effective: PE is one of the most affordable options for shrink packaging.

Clarity: Provides good clarity, allowing the product inside to be clearly visible.

Environmental Impact: PE is recyclable, making it a more eco-friendly option compared to PVC.

Shrinkage Rate: PE typically shrinks 60-70% in both length and width, creating a tight wrap around the product.

Strength: Offers moderate puncture resistance and durability.

2. Polyvinyl Chloride (PVC) Shrink Film

PVC shrink film is another commonly used material in shrink packaging. It is made from polyvinyl chloride resin and is known for its excellent shrink properties and clarity.

Key Characteristics of PVC Shrink Film:

Material: Made from polyvinyl chloride (PVC) polymer.

Cost: Generally more expensive than PE, but offers superior shrinkage and clarity.

Clarity: Offers high clarity and gloss, making it ideal for retail packaging where product visibility is important.

Environmental Impact: PVC is not as eco-friendly as PE, as it is not widely recyclable and can release harmful chemicals during production.

Shrinkage Rate: PVC has a high shrinkage rate, often exceeding 70%, providing a very tight and secure fit.

Strength: It has excellent puncture resistance and is often used for packaging delicate items like electronics.

3. Polyolefin (POF) Shrink Film

POF shrink film is made from a blend of polyethylene and polypropylene, which gives it unique characteristics that combine the benefits of both materials.

Key Characteristics of POF Shrink Film:

Material: Made from a blend of polyethylene and polypropylene (a copolymer).

Cost: More expensive than PE but generally less expensive than PVC.

Clarity: Offers excellent clarity, similar to PVC, and a glossy finish that enhances the visual appeal of the packaged product.

Environmental Impact: POF is considered more environmentally friendly than PVC because it is recyclable and does not release harmful substances.

Shrinkage Rate: POF has a high shrinkage rate (up to 80%), making it highly effective at conforming tightly to the product.

Strength: It has superior puncture resistance and is more flexible than PVC, making it ideal for packaging irregularly shaped or delicate items.

Comparison of PE Shrink Film and Other Shrink Films

To better understand the differences between these popular shrink films, it is helpful to compare them across key performance factors:

| Feature | PE Shrink Film | PVC Shrink Film | POF Shrink Film |

|---|---|---|---|

| Material | Polyethylene (LDPE or LLDPE) | Polyvinyl Chloride (PVC) | Polyethylene and Polypropylene (copolymer) |

| Cost | Low cost | Higher cost | Moderate cost |

| Clarity | Good transparency | Excellent transparency and gloss | Excellent transparency and gloss |

| Shrinkage Rate | 60-70% | 70-80% | Up to 80% |

| Environmental Impact | Recyclable, more eco-friendly | Not easily recyclable, more harmful | Recyclable, more eco-friendly |

| Puncture Resistance | Moderate resistance | High resistance | High resistance |

| Flexibility | Good flexibility | Less flexible, more rigid | Excellent flexibility |

| Best Used For | Retail, food, industrial, low-volume packaging | Retail, electronics, delicate items | Retail, food, multi-packs, irregular shapes |

Polyethylene (PE) shrink film is widely recognized as an effective and reliable material for food packaging. Its versatile properties make it an excellent choice for wrapping various food products, ensuring their freshness, safety, and appealing presentation. In the highly competitive food industry, packaging plays a crucial role in product appeal and consumer confidence, and PE shrink film delivers a variety of benefits that make it the packaging material of choice for food manufacturers.

1. Freshness and Preservation

One of the primary benefits of PE shrink film in food packaging is its ability to preserve food freshness. The shrink film creates a tight seal around the product, which helps protect it from external contaminants such as moisture, dust, and air. This barrier effect significantly extends the shelf life of food products by reducing exposure to the elements that can lead to spoilage, making it an ideal choice for perishable goods.

Prevents Moisture Loss: PE shrink film effectively traps moisture inside the package, keeping food products like fruits, vegetables, and meats from drying out.

Reduces Contamination: The film acts as a barrier, preventing contaminants such as bacteria, dust, and dirt from coming into contact with the food.

2. Protection Against Physical Damage

PE shrink film is durable and resilient, offering significant protection to food products during transport, handling, and storage. The film's puncture and tear resistance ensure that the food remains intact and free from physical damage. For delicate products such as fruits or fragile packaging like glass jars, PE shrink film provides an extra layer of protection against impacts or rough handling.

Durable Packaging: PE shrink film provides an extra protective layer that safeguards food items from physical damage, abrasions, or breakage during transit.

Prevents Crushing: The film helps maintain the integrity of the packaging, preventing products from being crushed or compromised in any way.

3. Extended Shelf Life

PE shrink film's tight seal and protective barrier not only preserve the product but also extend its shelf life. By keeping the food product sealed and free from external elements, the film helps maintain the food's flavor, texture, and nutritional value for a longer period.

Freshness Retention: The film helps retain the product’s freshness, preventing oxidation and spoilage, which is especially crucial for items like meat, cheese, and bakery products.

Prevents Freezer Burn: For frozen foods, PE shrink film helps protect against freezer burn by sealing out air and moisture, ensuring that frozen goods maintain their quality during storage.

4. Tamper-Evident Packaging

PE shrink film creates a tamper-evident seal, which enhances product security and consumer confidence. The shrink film makes it difficult to remove or alter the packaging without visibly damaging the film, ensuring that customers receive the product in its original, unaltered state. This feature is particularly important in food packaging, where safety and trust are top priorities.

Increased Consumer Trust: The tamper-evident feature ensures that customers can be confident in the safety of the food they are purchasing.

Prevents Theft: Tamper-proof packaging helps reduce the risk of theft or unauthorized handling during storage and distribution.

5. Versatility for Different Food Products

PE shrink film is highly versatile, making it suitable for a wide range of food products, from fresh produce to processed foods. It can be used to package individual items as well as multi-pack bundles, offering flexibility for manufacturers and retailers. The film can also be easily customized to fit different product sizes, shapes, and packaging formats.

Flexible Packaging: Whether wrapping a single item like a piece of fruit or a larger multi-pack of beverages, PE shrink film can accommodate different shapes and sizes.

Customizable Branding: The film can be printed with branding, product information, and other marketing materials, helping manufacturers create attractive packaging that appeals to consumers.

6. Eco-Friendly and Recyclable

With growing concerns about sustainability and environmental impact, PE shrink film offers a more eco-friendly packaging solution compared to some other materials. PE is a recyclable material, and its use in food packaging is increasingly being recognized as a more sustainable option. Many manufacturers are choosing PE shrink film over non-recyclable options like PVC due to its recyclability and lower environmental impact.

Recyclable: PE shrink film can be recycled after use, helping to reduce packaging waste and contributing to a circular economy.

Lower Carbon Footprint: The production of PE shrink film typically has a lower environmental impact compared to other types of shrink films, such as PVC, making it a more sustainable choice.

7. Cost-Effective Solution

PE shrink film is one of the most cost-effective packaging options available. It is affordable to produce, and the shrink-wrapping process is relatively simple and efficient, which helps reduce overall packaging costs. For businesses, this translates into a more economical solution, especially when packaging products in high volumes.

Reduced Packaging Costs: PE shrink film's affordability helps businesses keep packaging costs low while still providing high-quality protection.

Efficient Packaging Process: The use of PE shrink film can improve production efficiency, reducing both labor and material costs.

8. Enhanced Presentation

PE shrink film provides a clear, glossy finish that enhances the visual appeal of food products. The transparent film allows consumers to see the product clearly, which can be particularly important for fresh produce, snacks, or gourmet items. The neat and professional look provided by shrink-wrapping helps attract attention on store shelves.

Appealing Display: The film creates a clean, polished look that highlights the food product, making it more visually appealing to customers.

Product Protection and Visibility: PE shrink film offers the best of both worlds—protection for the food and an attractive presentation.

Table: Benefits of PE Shrink Film for Food Packaging

| Benefit | Description |

|---|---|

| Freshness & Preservation | Seals in moisture and protects against external contaminants, extending shelf life and preserving taste. |

| Protection Against Damage | Durable and resistant to punctures and tears, protecting food products from physical damage. |

| Extended Shelf Life | Helps preserve the flavor, texture, and nutritional value of food, while preventing freezer burn. |

| Tamper-Evident Packaging | Provides a tamper-proof seal, ensuring product safety and increasing consumer trust. |

| Versatility for Food Products | Can be used for a variety of food products, offering flexible packaging solutions for different shapes. |

| Eco-Friendly | PE is recyclable, making it a more sustainable option compared to non-recyclable shrink films. |

| Cost-Effective | Low-cost material and efficient packaging process help reduce overall packaging expenses. |

| Enhanced Presentation | Transparent and glossy finish improves product visibility and makes the food more appealing on the shelf. |

Selecting the correct PE shrink film for your specific application is essential to ensure optimal product protection, presentation, and cost-effectiveness. With its versatility, PE shrink film is commonly used across many industries, including food packaging, retail packaging, and industrial packaging. However, different types of PE shrink films vary in their characteristics and performance, so understanding your requirements is crucial when making the choice. Here are key factors to consider when selecting the right PE shrink film for your application:

1. Product Type and Size

The type of product you are packaging will significantly impact the type of PE shrink film you should choose. Different products have varying shapes, sizes, and sensitivities to handling, all of which should be taken into account.

Small or Irregularly Shaped Products: For small, delicate, or irregularly shaped products, a thinner, more flexible PE shrink film (such as LDPE) may be suitable. This allows the film to easily conform to the shape of the product, ensuring a tight, wrinkle-free fit.

Bulkier or Heavier Products: For larger or heavier items, such as multi-packs, bottled goods, or industrial products, a thicker PE shrink film (such as LLDPE) may be required. It provides better strength and durability, ensuring that the packaging holds up during transportation and storage.

2. Shrinkage Rate

The shrinkage rate is an important factor to consider when choosing a PE shrink film, as it determines how tightly the film will conform to the product after being heated. The ideal shrinkage rate depends on the specific application:

High Shrinkage Rate: If you need the film to shrink tightly around the product, ensuring a smooth, secure fit, choose a PE film with a higher shrinkage rate (around 70–80%). This is often used for food packaging or irregularly shaped products where a tight seal is required.

Low Shrinkage Rate: For products that do not require an extremely tight fit, such as some retail packaging or bulk packaging, a PE shrink film with a lower shrinkage rate (around 60%) may be more suitable. This will allow for slightly looser wrapping without compromising the protection.

3. Durability and Strength

The durability of the PE shrink film is a critical consideration, especially for products that will undergo rough handling or long-distance transportation. The film's puncture resistance and tear strength determine how well it can withstand external forces.

High Puncture Resistance: For products that are vulnerable to external impacts, such as fragile goods or perishable items like meats and fruits, choose a PE shrink film with excellent puncture resistance, such as LLDPE or MDPE. These films provide added durability during handling and transport.

Moderate Strength: For less delicate items, such as cans or bottles, a standard LDPE shrink film may provide adequate protection without being overly thick or expensive.

4. Environmental Considerations

As sustainability becomes a growing concern in the packaging industry, it's important to consider the environmental impact of your packaging materials. PE shrink film is an eco-friendly option compared to other shrink films, such as PVC, because it is fully recyclable.

Recyclability: PE shrink film is made from polyethylene, a recyclable plastic. If your business aims to reduce its environmental footprint, opting for PE shrink film is an effective way to meet sustainability goals.

Environmental Certifications: Look for PE shrink films that have environmental certifications or meet specific regulations regarding recyclability and sustainability.

5. Clarity and Visual Appeal

PE shrink film is available in both clear and colored variations, allowing businesses to select the right option based on product visibility and branding needs.

High Clarity: For products where visual appeal and consumer product visibility are important, such as food packaging or retail items, opt for a high-clarity PE shrink film. This allows the consumer to see the product clearly, making it more attractive on store shelves.

Colored or Printed Film: For branding purposes or when you need to differentiate product lines, a colored PE shrink film or one with custom printing can help convey your brand’s message. Colored shrink films can also be used for seasonal or promotional packaging.

6. Heat Resistance

Heat resistance is an important factor in determining how well the PE shrink film will perform during the shrink-wrapping process. PE shrink film is generally designed to withstand the heat necessary for shrinkage, but it is important to ensure the film can handle the temperatures required for your specific application.

Standard Heat Resistance: Most PE shrink films are designed to shrink effectively at temperatures between 120°C and 160°C (248°F to 320°F), making them suitable for typical shrink-wrapping applications.

High Heat Resistance: If you are working with products that require a higher shrink temperature or that are heat-sensitive, look for PE shrink films designed with higher heat resistance. These films can withstand higher temperatures without deforming.

7. Cost and Budget

Cost is often a deciding factor when selecting packaging materials, and PE shrink film is known for being a cost-effective solution compared to other shrink films like PVC or POF. The cost will depend on the type of PE film, its thickness, and the required performance properties.

Cost-Effective Solutions: If you are looking for an affordable packaging option, PE shrink film provides excellent value for its performance, especially when buying in bulk for large-scale production.

Premium Options: For applications that require extra durability, high clarity, or specific properties such as higher puncture resistance, you may need to invest in a premium PE shrink film, which may cost slightly more but offer added benefits in terms of strength and protection.

Polyethylene (PE) shrink film has been a staple in the packaging industry for many years due to its versatility, durability, and cost-effectiveness. As consumer demand for sustainable, high-performance packaging continues to grow, advancements in PE shrink film technology are evolving to meet new challenges and opportunities. These trends are shaping the future of PE shrink film, making it an even more efficient, eco-friendly, and innovative solution for various industries. Let's explore some of the key trends that are driving the future of PE shrink film technology.

1. Advancements in Biodegradable and Sustainable Materials

As environmental concerns rise, there is a growing push for packaging solutions that reduce plastic waste. This trend has led to the development of biodegradable and compostable PE shrink films, which are derived from renewable resources. These materials break down more easily in landfills or composting facilities, offering a more sustainable option compared to traditional PE films.

Bio-based PE Shrink Film: Bio-based PE, made from plant-based feedstocks such as sugarcane or corn, is gaining traction. This material maintains the same performance characteristics as traditional PE but with a significantly lower carbon footprint.

Recyclable Films: The push for a circular economy is driving the development of more recyclable PE shrink films, ensuring that after use, the films can be efficiently recycled and repurposed.

2. Increased Use of Recycled Materials

One of the most significant shifts in the PE shrink film industry is the use of recycled materials in film production. Companies are increasingly incorporating post-consumer recycled (PCR) polyethylene into their films. This helps reduce the demand for virgin plastic while maintaining the performance and durability of the shrink film.

Closed-Loop Recycling: Innovations in closed-loop recycling processes are making it easier to collect and reuse PE shrink films. This helps reduce the overall environmental impact by minimizing plastic waste and reducing the need for new raw materials.

Improved Reprocessing Technologies: Advancements in the ability to recycle PE films more efficiently will likely lead to the widespread use of recycled content in PE shrink film production, reducing waste and supporting sustainability goals.

3. Enhanced Customization and Printing Capabilities

Packaging aesthetics are becoming increasingly important, particularly for consumer-facing products. The demand for customized PE shrink films with enhanced graphic designs and printed logos is on the rise. In response, manufacturers are improving printing technologies and film customization options.

High-Quality Graphics and Printing: Advances in digital printing and flexographic printing technologies allow for sharper, more vibrant designs on PE shrink films. This enables brands to create eye-catching packaging with intricate designs and high-quality branding elements.

Custom Shrink Films: As consumer preferences continue to evolve, the need for personalized packaging solutions grows. Manufacturers are offering more customizable shrink films, allowing businesses to cater to specific packaging needs with features like color changes, textures, and tailored sizes.

4. Higher Shrinkage Performance and Efficiency

In order to meet the growing demand for improved packaging performance, PE shrink films are evolving to provide better shrinkage properties, ensuring a tighter, smoother fit around products. Higher shrinkage rates are crucial for ensuring that packaging conforms tightly to irregularly shaped products or multi-packs.

Low Temperature Shrinkage: New PE shrink films are being designed to provide high shrinkage performance at lower temperatures, reducing the energy required for the shrink-wrapping process and improving overall efficiency.

Faster Shrinkage Time: Manufacturers are also working to reduce the time required for the shrinkage process, improving productivity and speeding up the packaging line.

5. Smart Packaging Integration

The integration of technology into packaging is a rapidly growing trend, and PE shrink film is no exception. Smart packaging technologies are being embedded into PE shrink films, providing enhanced product tracking, tamper-evidence, and consumer interaction.

QR Codes and RFID Tags: PE shrink films can be printed with QR codes or integrated with RFID tags to allow consumers to interact with the packaging. This provides a way for brands to offer more information about the product or enhance the consumer experience through interactive marketing.

Temperature Sensors: Some PE shrink films are being developed with built-in temperature sensors, allowing consumers or distributors to verify if the product has been stored or transported at the correct temperatures. This technology is especially useful in the food, pharmaceutical, and perishable goods industries.

6. Performance Improvements in Barrier Properties

PE shrink films are being developed with enhanced barrier properties to protect products from external elements like moisture, oxygen, and UV light. This is especially important for food packaging, where protecting the integrity of the product is crucial.

Barrier Coatings: New barrier coatings are being applied to PE shrink films to enhance their protective capabilities. These coatings improve the film's resistance to moisture and oxygen, making it ideal for packaging perishable goods such as meats, dairy products, and baked goods.

Light Protection: Advances in UV-blocking technology are helping to improve the light resistance of PE shrink films, which is important for products sensitive to light degradation, such as vitamins, cosmetics, and pharmaceuticals.

7. Automation and Improved Efficiency in Packaging Lines

The trend toward automation in packaging lines is gaining momentum, and PE shrink film technology is evolving to integrate seamlessly with automated systems. Automation helps improve packaging efficiency, reduce labor costs, and increase the speed of production.

Automatic Shrink Wrapping Systems: Newer PE shrink film machines are designed to integrate easily with automated packaging lines, allowing for faster and more consistent shrink-wrapping of products. These systems are capable of packaging large volumes of products with minimal human intervention.

Smart Machines for Quality Control: Automated systems are incorporating smart technology for better quality control, ensuring consistent shrinkage, accurate film application, and reduced waste.

The future of PE shrink film technology is exciting, with advancements in sustainability, customization, efficiency, and integration driving the industry forward. From biodegradable materials to enhanced barrier properties and smart packaging features, PE shrink films are evolving to meet the changing needs of businesses and consumers. These innovations will not only improve the performance and versatility of PE shrink films but also contribute to a more sustainable, efficient, and consumer-friendly packaging landscape.

At Jiuteng PE Shrink Film Factory, we are committed to staying at the forefront of these innovations, offering high-quality PE shrink films that meet the latest technological advancements and environmental standards. Our products are designed to provide superior performance while supporting your business's sustainability goals. Whether you're packaging food, beverages, or industrial goods, Jiuteng PE Shrink Film Factory is your trusted partner for all your shrink film needs.