Packaging buyers rarely argue about whether shrink film is useful—they argue about which film delivers the look, line speed, and protection they need without surprises. Polyolefin (POF) shrink film has become the default choice in many markets because it combines retail-ready optics with reliable runnability across a wide range of products.

Shrink film is a heat-shrinkable plastic film used to wrap products and then tightened with controlled heat. Once heated, the film contracts around the item, creating a package that is typically tamper-evident, scuff-resistant, and shelf-attractive. In modern packaging, shrink film matters because it can do multiple jobs at once:

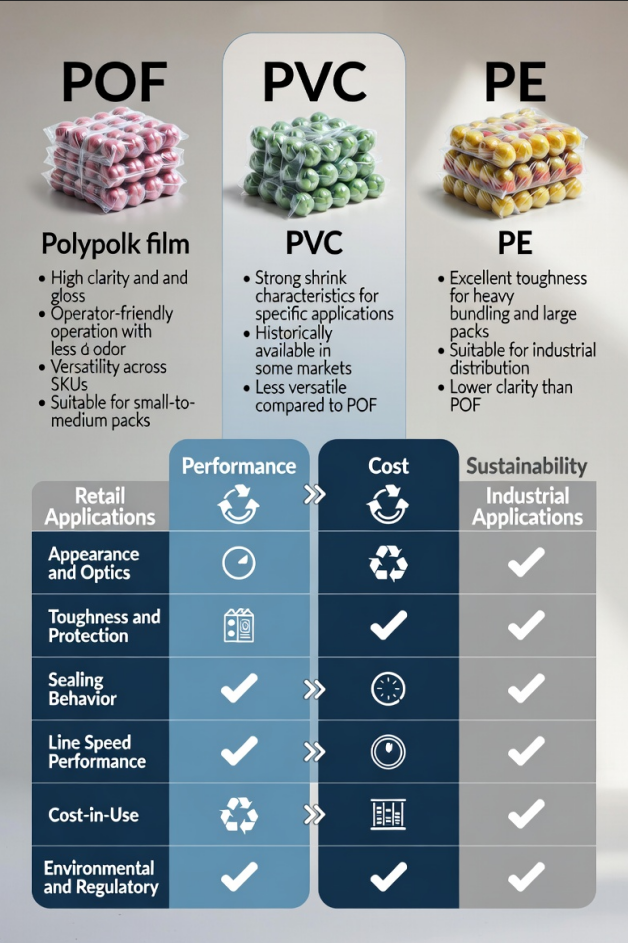

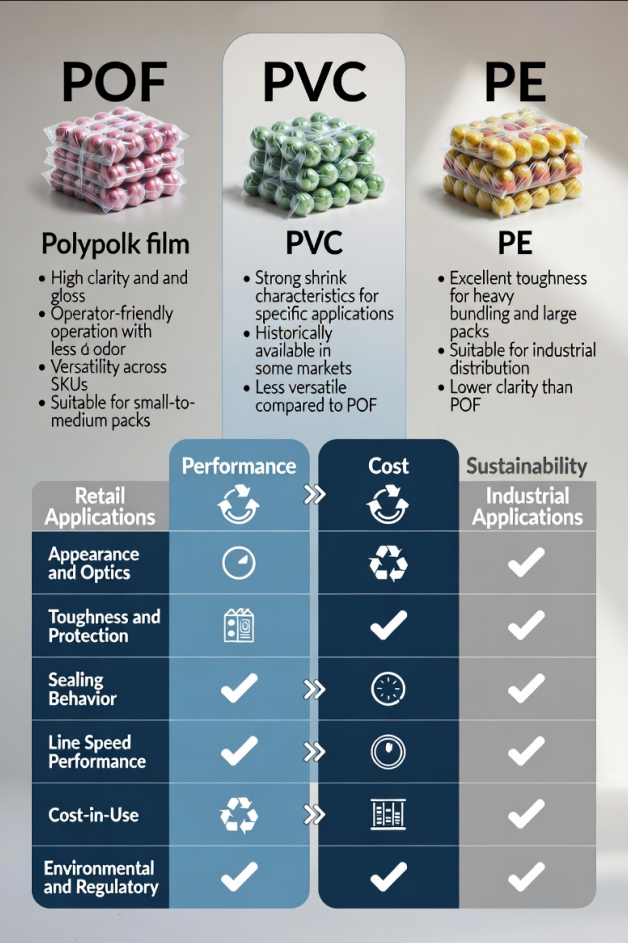

Where polyolefin fits among common shrink film materials

In day-to-day packaging conversations, shrink film is commonly grouped into three families:

POF often ends up as the "middle path" that still looks premium: clearer than typical PE in many retail applications, more flexible than many PVC setups, and easier to standardize across diverse SKUs.

Brief history and rise of POF shrink films in global markets

POF shrink films gained traction as packaging lines became faster and brand presentation became more important. As global retail expanded and packaging standards tightened, demand increased for films that could deliver:

Over time, multi-layer POF designs and improved orientation technology made it possible to achieve thin gauges with high strength, helping POF become a mainstream choice for both cost control and premium presentation.

Polyolefin (POF) shrink film is a heat-shrinkable, oriented film made primarily from polyolefin-based polymers. In packaging terms, it's the clear film you typically see around boxed cosmetics, printed materials, toys, household items, multipacks, and many food and non-food consumer products.

Definition of polyolefin shrink film

A practical definition used by packaging engineers is:

While shrink films exist in many plastics, POF is engineered specifically to be a stable, versatile shrink film rather than a "generic plastic film that happens to shrink."

What "polyolefin" means in polymer science

"Polyolefin" refers to a family of polymers made from olefin (alkene) monomers—most commonly:

Polyolefins are valued because they are chemically resistant, low in density (lightweight), and can be engineered across a wide range of stiffness, clarity, and toughness depending on molecular structure and additives.

Typical polymer blends used in POF shrink films

Commercial POF shrink films are often based on combinations such as:

A key point: POF shrink film is usually not a single "pure" polymer. It's a designed structure where each layer has a job—one layer may be optimized for sealing, another for strength, another for machinability.

How POF shrink film differs from generic plastic films

Generic plastic films (like simple PE sheeting) are often made to be strong or cheap, but not necessarily to shrink evenly with a retail finish. POF shrink film differs in a few decisive ways:

POF shrink film manufacturing is a chain of decisions that all show up on the finished roll: clarity, gloss, shrink balance, sealing, and consistency. While each manufacturer has proprietary details, the main steps are broadly consistent across the industry.

Raw material selection and resin composition

Production begins with selecting resin grades and additive packages that fit the target product:

Even small changes in resin consistency, contamination control, or additive dosing can affect haze, gel count, sealing behavior, and shrink appearance.

Co-extrusion process explained

Most POF shrink films are produced by co-extrusion, meaning multiple molten polymer streams are combined into a single multi-layer film before it solidifies.

Why co-extrude?

After co-extrusion, the film is typically formed into a primary sheet/tube and then prepared for orientation.

Orientation and biaxial stretching

Orientation is the step that transforms a "plastic film" into a "shrink film."

Biaxial stretching aligns polymer chains and creates stored elastic energy. When the film is reheated in a shrink tunnel, those chains relax toward their original state, and the film shrinks.

This step strongly influences:

If orientation conditions are inconsistent (temperature profile, stretch ratio, speed), you can see issues such as uneven shrink, wrinkling, dull appearance, or weak spots.

Cooling, winding, and quality control steps

After orientation, the film must be stabilized:

Consistency at winding and slitting is especially important because many film “problems” blamed on formulation are actually caused by tension, handling, or roll build quality.

Common thickness ranges and formats

POF shrink film is available in a wide span of thicknesses depending on the product and packaging style.

Common thickness ranges (typical industry usage):

Common formats:

A spec sheet can be long, but most buying decisions come down to a handful of properties that determine appearance, protection, and line performance. The most useful approach is to connect each property to what you'll actually see on your packaged product.

Clarity and optical properties

Optical performance is usually described using:

Optics are influenced by resin selection, melt cleanliness, orientation uniformity, and surface quality. For retail packaging, clarity and gloss can be decisive because they affect perceived product quality before the customer even reads the label.

Shrink ratio and shrink force

Two films can have similar shrink percentages and behave very differently on product.

Why this matters:

A "good" shrink profile is the one that matches your product rigidity and your tunnel's heat distribution.

Tensile strength and puncture resistance

These properties determine how well the film survives:

For boxed items with crisp corners, puncture resistance is often more predictive of field performance than tensile strength alone.

Seal strength and sealing temperature range

Sealing is where packaging productivity lives or dies.

A wider seal window is valuable when:

Flexibility and low-temperature performance

Many packages don't live in a perfect climate. Flexibility matters for:

POF is often chosen because it can remain flexible across a broad temperature range, reducing the risk of brittle failure compared with films that become stiff or crack-prone in the cold.

|

Property |

Key Points |

Impact on Packaging |

|

Clarity & Optical Properties |

Haze, gloss, defects; influenced by resin and film quality |

Clear, shiny packaging improves retail appearance |

|

Shrink Ratio & Shrink Force |

Film contraction % and pulling strength |

Affects package conformity; too high crushes products, too low leaves loose corners |

|

Tensile Strength & Puncture Resistance |

Resistance to stretching, tearing, and piercing |

Ensures survival during handling, transport, and sharp edges |

|

Seal Strength & Temperature Range |

Strength of seams; forgiving seal window |

Reliable seals reduce scrap, downtime, and rework |

|

Flexibility & Low-Temp Performance |

Remains pliable in cold or harsh conditions |

Prevents brittle cracking; maintains package integrity in cold storage or shipping |

POF shrink film is not a single "one-size" material. Manufacturers tune it through layer design, resin selection, and orientation settings to achieve different sealing behavior, strength, optics, and runnability. Understanding the main categories makes it much easier to match film to product and machine.

Standard (non-crosslinked) POF is the most widely used grade for everyday shrink wrapping.

Typical characteristics

Where it's commonly used

Standard POF is often the best starting point for trials because it tends to provide a stable baseline across different packaging environments.

Cross-linked POF is engineered so polymer chains are partially "linked," improving certain mechanical and thermal behaviors. In practice, cross-linked films are often selected when packaging demands are more severe or line speeds are higher.

Typical characteristics

Where it's commonly used

Cross-linked film can be an excellent choice when standard film runs close to its limits (frequent breaks, punctures, or inconsistent shrink appearance at speed).

This is a format choice more than a resin-grade choice, but it strongly affects machine compatibility and workflow.

Centerfold (CF) film

Single-wound (flat) film

Selection rule Choose the format that matches your equipment first—then choose the grade and thickness. A great film in the wrong format is still the wrong film.

Micro-perforated (or vented) POF includes controlled perforations that allow trapped air to escape during shrinking.

Why it matters Air trapped between film and product can cause:

Common use cases

Micro-perforation must be tuned carefully: too little venting may not solve the problem; too much can reduce protection and affect appearance.

Food-grade and FDA-compliant POF films

"Food grade" is not a generic label—it depends on the specific film formulation, manufacturing controls, and compliance documentation for the target market.

Key points in practical terms

For food packaging, procurement should treat compliance as part of the specification, not a marketing phrase.

|

Type / Grade |

Key Characteristics |

Common Applications |

|

Standard POF |

Balanced clarity, gloss, and toughness; reliable sealing; good shrink conformity |

Retail cartons, cosmetics, household items, printed products, books, stationery |

|

Cross-linked POF |

Higher toughness, tear resistance, supports thinner films, stable on high-speed lines |

High-speed automated lines, sharp-edged products, heavy handling stress |

|

Film Format |

Centerfold (CF) for bagged wraps; Single-wound (flat) for automated or specialty lines |

Depends on machine type and packaging workflow |

|

Micro-perforated POF |

Controlled vents to release trapped air, reducing ballooning and wrinkles |

Packs with void space, bundles, printed stacks, irregular shapes |

|

Food-grade / FDA POF |

Formulated and documented for safe direct/indirect food contact |

Food packaging requiring compliance with FDA or regional regulations |

POF is often compared with PVC and PE because those materials cover most shrink applications worldwide. The best choice depends on the balance you need between appearance, toughness, sealing behavior, cost-in-use, and perception/regulation.

In many modern packaging operations, POF is chosen as a more versatile, broadly accepted solution for retail packaging and mixed-product environments.

PE shrink film is frequently used for heavier-duty bundling and larger packs, while POF dominates smaller retail packs where optics and crisp finish matter.

Comparing film types only by "price per roll" is risky. Real cost is usually driven by:

Many buyers find that a film with a slightly higher unit price can still reduce total cost if it improves throughput and reduces scrap.

Environmental and regulatory requirements vary by region and application, but common decision drivers include:

A practical approach is to evaluate both: (1) compliance and customer expectations, and (2) measurable waste reduction opportunities on the production floor.

|

Film Type |

Strengths |

Typical Use Cases |

Notes / Considerations |

|

POF |

High clarity and gloss; versatile; easy, neat finish; compatible with retail equipment |

Small-to-medium retail packs, mixed SKUs, modern retail presentation |

Slightly higher unit cost may reduce total cost via less scrap and downtime |

|

PVC |

Strong shrink characteristics; historically available in some markets |

Certain traditional shrink applications; niche markets |

Less versatile; odor during processing; declining use in modern retail |

|

PE |

Excellent toughness; ideal for heavy-duty bundling and large packs |

Cases, beverages, industrial distribution, large-format loads |

Lower clarity; better for strength than retail appearance |

POF's popularity comes from its ability to serve very different industries with the same core strengths: clean appearance, reliable sealing, and durable protection.

Food packaging (bakery, produce, frozen foods)

POF is used in food-related packaging where clarity, cleanliness, and consistent sealing are important.

In food applications, the correct film grade, hygiene controls, and compliance documents are part of the selection—not optional extras.

Consumer goods and retail packaging

This is one of POF's strongest areas.

Pharmaceuticals and medical products

For pharma and medical items, shrink film is often used as tamper evidence and secondary protection rather than as a sterile barrier.

These applications typically require strong process control, consistent roll quality, and careful attention to documentation and traceability expectations.

Printed materials and stationery

POF performs well on printed products because it can protect surfaces while keeping the product visible.

Key needs here include smooth optics (so printing looks sharp) and shrink behavior that does not distort the pack.

Industrial and multi-pack applications

POF is also used beyond retail—especially for smaller industrial items or multi-packs where clarity and a tight wrap are desired.

For heavier industrial bundling, some operations shift toward PE, but POF remains a strong choice for many small-to-mid pack sizes.

|

Industry / Application |

Typical Uses |

Key Requirements |

|

Food Packaging |

Bakery trays, boxed baked goods, produce packs, frozen-food multipacks |

High clarity, hygiene control, consistent sealing, regulatory compliance |

|

Consumer Goods & Retail |

Cosmetics, personal care, household items, toys, promotional bundles |

High clarity and gloss, neat corners, clean seals for premium presentation |

|

Pharmaceutical & Medical |

Carton overwrap for tamper evidence, bundling of boxed products, scuff protection |

Process control, consistent roll quality, traceability documentation |

|

Printed Materials & Stationery |

Books, notebooks, greeting cards, brochures, catalogs, stationery sets |

Smooth optics, distortion-free shrink, surface protection |

|

Industrial & Multi-Pack |

Hardware items, small components, multipacks, light-to-medium bundling |

Tight, stable wrap; clarity; clean presentation; small-to-mid pack focus |

POF's advantages are best understood in terms of what they do for your product, your operators, and your line performance.

High clarity and shelf appeal

Wide sealing window and easy machinability

Strong, durable, and tear-resistant

Odor-free and safer for operators

Suitable for high-speed packaging lines

|

POF Advantage |

Key Benefits |

Impact / Use |

|

High Clarity & Shelf Appeal |

Clear visibility, high gloss, low haze |

Enhances brand presentation and retail-ready look |

|

Wide Sealing Window & Machinability |

Reliable seals across varying speeds and operators |

Reduces rejects, ensures stable throughput and clean appearance |

|

Durable & Tear-Resistant |

Tough multi-layer structure, balanced tensile and puncture strength |

Protects products during handling, shipping, and distribution |

|

Odor-Free & Operator-Friendly |

Cleaner processing environment |

Improves worker comfort and meets workplace standards |

|

High-Speed Line Compatibility |

Consistent roll build, predictable shrink, cross-linked options |

Supports automation, reduces defects at high throughput |

POF shrink film is a strong all-rounder, but it is not a universal solution. The fastest way to avoid packaging headaches is to understand where POF can be less forgiving—then design around those limits with the right grade, thickness, and equipment settings.

Cost compared to PVC

In many markets, POF can cost more than PVC on a price-per-kilogram basis. That difference is real, but it is also incomplete as a comparison.

What often changes the decision is cost-in-use, including:

In other words, PVC may look cheaper on paper, while POF can be cheaper in operation—especially when the packaging line is fast or the product mix is complex.

Heat requirements and equipment compatibility

POF is a heat-shrink material with a defined processing window. Problems usually happen when the film is asked to shrink or seal outside that window.

Common equipment-related considerations include:

A key practical point: POF performance is highly repeatable when the machine is stable. When the machine is unstable, POF does not “hide” the problem—it shows it.

Shrink force considerations for delicate products

Shrink packaging is not only about how much the film shrinks; it is also about how strongly it pulls while shrinking.

Shrink force becomes a risk when packaging:

How shrink force shows up in real packs:

How to manage it:

Storage and handling best practices

Even high-quality film can perform poorly if stored or handled badly. POF is stable when treated correctly, but sensitive enough that rough storage can show up on the packaging line.

Best practices that reduce run issues:

Handled well, POF typically provides consistent sealing and shrink appearance across long production runs.

Sustainability discussions around shrink film are rarely about one perfect material—they're usually about measurable improvements: less material used, less waste produced, and clearer compliance for the target market. POF is often selected because it supports those practical goals, especially through downgauging and stable process yield.

Recyclability of POF shrink film

POF is based on polyolefin polymers, which are widely used in packaging. However, recyclability is not only about polymer family—it depends on local collection systems, sorting behavior, and how the film is used.

Important realities:

For many brand owners, the immediate sustainability win with POF is not "perfect recycling," but material reduction and defect reduction: using less film per pack and scrapping fewer packages.

Compliance with food-contact and safety regulations

Sustainability and compliance often overlap. Many customers expect shrink film used around food or sensitive consumer goods to come with robust documentation and controlled formulations.

Key considerations include:

Compliance isn't a marketing claim; it's a documentation and process-control discipline.

Comparison of environmental impact with PVC

Environmental impact discussions vary by region and policy, but in practical procurement, PVC often faces stronger scrutiny due to end-of-life concerns and how it interacts with mixed recycling streams.

POF is frequently viewed as the more broadly accepted alternative because:

A useful way to frame it internally is: POF typically aligns better with modern packaging material strategies, particularly those focused on polyolefin-based systems and reduced material usage.

Trends toward downgauging and material reduction

Downgauging is one of the most direct sustainability levers in shrink packaging. If you can reduce thickness while maintaining performance, you reduce:

POF—especially higher-performance constructions—often enables downgauging because of its strength-to-thickness efficiency and stable sealing behavior when matched to the right equipment settings.

That said, downgauging should be validated carefully. If thinner film increases breakage, punctures, or rework, the sustainability gains disappear quickly. The best downgauging projects are those that improve both material use and operational stability.

Selecting the right POF film becomes straightforward when you treat it as a matching problem: product risk + appearance requirements + machine capability. The best film is the one that meets your performance goals while running reliably at your target speed.

Film thickness selection guidelines

Thickness is a primary lever, but it should be chosen based on real packaging stress, not habit.

Practical starting points (typical use patterns):

How to decide quickly:

Matching shrink film to product shape and weight

Shape matters as much as weight. A light product with sharp corners can be harder on film than a heavier product with smooth geometry.

Consider the following risk factors:

For difficult shapes, solutions often include:

Choosing between standard and cross-linked POF

A practical decision rule is to start with standard POF unless you have clear reasons not to—then upgrade to cross-linked when the process or product demands it.

Standard POF is usually best when:

Cross-linked POF often makes sense when:

Think of cross-linked film as a way to increase operational margin: fewer failures when conditions are demanding.

Film selection should be confirmed against how your equipment actually behaves, not how it behaves on a perfect day.

Checklist for compatibility:

A useful trial method:

|

Selection Factor |

Guidelines / Options |

Impact / Notes |

|

Film Thickness |

10–12µm: lightweight, premium packs; 15µm: general-purpose; 19–25µm: heavy items, sharp edges, multi-packs |

Thicker film prevents punctures, splits; thinner film can save material if line is stable |

|

Product Shape & Weight |

Sharp edges, irregular shapes, flexible items, high-gloss surfaces |

Consider higher thickness, stronger grade, venting, or controlled shrink to reduce defects |

|

Standard vs Cross-Linked POF |

Standard: moderate speed, mixed SKUs, general-purpose; Cross-linked: high-speed, sharp edges, downgauging, demanding lines |

Cross-linked increases operational margin and durability under stress |

|

Equipment Compatibility |

Sealer stability, seal window, tunnel heat distribution, line speed |

Test difficult and high-volume SKUs; track seals, appearance, defect rate, downtime |

|

Trial & Validation |

Run meaningful tests on most challenging and highest-volume SKUs |

Ensures film choice meets performance goals under real conditions |

Most shrink-wrap problems look like "film issues," but they usually come from a mismatch between film type + product geometry + sealing/tunnel settings + roll handling. The fastest troubleshooting method is to identify where the defect is created: at sealing, during shrinking, or during unwind/transport.

Poor shrink appearance and wrinkles

Wrinkles, "dog ears," loose corners, and wavy surfaces typically indicate that the film is not shrinking evenly—or is shrinking before trapped air can escape.

Weak seals or seal burn-through

Seal failures often show up as splits during shrink, open seams at corners, or seals that peel easily. Burn-through shows as holes, thinning, or brittle seal edges.

Film breakage or tearing during packaging

Breaks can occur at unwind, through the sealer, or in the tunnel. The break location is a clue.

How film selection affects performance

Film selection influences troubleshooting outcomes more than many teams expect.

A useful rule: change settings before changing film—unless repeated trials show the film's performance window is too narrow for your line.

POF shrink film is engineered to perform consistently, but it is still a precision packaging material. Good storage and handling protect optics, unwind stability, and sealing behavior.

Proper storage temperature and humidity

Stable conditions help prevent winding deformation, static problems, and handling issues.

Humidity control matters because extremely dry environments can increase static, while poor moisture management can cause handling and contamination problems.

If a roll has been stored in cold conditions, allow time for acclimation before production to reduce condensation and unwind issues.

Handling tips to avoid film damage

Many "film defects" originate from mechanical damage during transport and staging.

Safety considerations for operators

Shrink packaging involves heat and moving webs; safety should be built into routine operation.

A clean, well-managed workstation improves both safety and packaging consistency.

POF shrink film continues to expand because it fits three long-term pressures: retail presentation, automation, and material-efficiency.

Growing demand in food and retail sectors

Advances in material science and film performance

Film performance improvements typically focus on:

These advances show up as fewer line stops, more stable appearance across shifts, and more reliable performance on demanding products.

Sustainability-driven innovation

Sustainability improvements in shrink film are increasingly practical and measurable:

In many operations, the biggest near-term sustainability gains come from material reduction and waste prevention, not from changing the logo on a spec sheet.

Regional market differences and growth outlook

Regional differences often come from:

Despite differences, the broader direction is consistent: more automation, more emphasis on appearance, and more pressure to reduce material use—factors that generally support POF adoption.

15. Frequently Asked Questions About POF Shrink Film

Is POF shrink film food-safe?

Can POF replace PVC shrink film?

What thickness should I choose?

Is POF recyclable?

POF shrink film delivers clear, strong, and reliable packaging for a variety of products. Jtpackage provides carefully selected film grades and formats to fit different machines and product types. With proper handling and trial validation, our solutions help maintain consistent presentation, protect goods during distribution, and keep production efficient, making Jtpackage a dependable choice for high-quality shrink packaging.