Packaging in retail does far more than simply hold a product. It keeps items safe through every step of delivery and storage, helps them stand out among competitors on store shelves, and often carries branding that shapes customer impressions. When retailers choose shrink films for wrapping, many turn to Polyolefin (POF) because it handles these tasks effectively in everyday operations.

POF shrink film comes from polyethylene and polypropylene blends formed into thin, multi-layer sheets. Heat causes the film to pull tight around whatever it covers, forming a close-fitting barrier. This process creates packages that look sharp while staying protected. Stores dealing with everything from groceries to household goods find this material practical because it fits a wide range of needs without complicating workflows.

Retail spaces demand packaging that works reliably day after day. Products move from warehouses to trucks, then onto shelves and finally into shopping bags. Throughout this chain, the wrap must hold up to handling, stacking, and display conditions. POF meets these demands by offering a combination of clear views, solid strength, and straightforward application that suits busy retail environments. Small details, like how the film seals without leaving sticky residue on machines, keep production running smoothly and reduce cleaning time for operators. In practice, teams notice fewer interruptions, which adds up over long shifts.

The structure of POF film gives it qualities that match retail requirements well. Multiple layers work together to provide both toughness and transparency. Once shrunk, the film hugs product shapes closely, avoiding loose spots or creases that could detract from appearance. This tight fit gives packages a finished look right out of the tunnel.

One noticeable feature is the level of clarity. Customers can see items inside without obstruction, which matters when shoppers want to check details before buying. This transparency helps with items like fresh foods or colorful merchandise where visual appeal plays a big role in sales. The glossy surface adds a polished touch that makes even simple bundles look intentional and cared for. Store managers often comment on how wrapped goods catch light better, drawing eyes in crowded aisles.

Strength is another area where POF performs solidly. The film stands up to everyday knocks and scrapes that happen during stocking or transport. It resists splitting or poking through, keeping contents secure until they reach the buyer. For stores with high turnover, this means fewer instances of damaged stock needing to be marked down or removed. Warehouse staff appreciate not having to repack torn bundles as often.

Application remains flexible across different setups. Packaging lines can run the film through standard sealing and heating equipment without frequent changes. This ease allows retailers to wrap single items or create bundles for promotions as needed. Switching between product types becomes less of a hassle, especially during busy seasons when assortments change quickly. Operators get used to the feel of the material quickly, leading to steady output.

Temperature handling adds further practicality. The film stays usable in cooler sections or regular store conditions, making it appropriate for varied product storage without special precautions. Staff can stock wrapped goods confidently, knowing the packaging won't fail in refrigerated displays or warmer backrooms. This reliability simplifies planning across mixed inventory.

Retail packagers often weigh POF against alternatives like PVC or basic polyethylene films. PVC provides decent shrinkage and initial clarity, but it can stiffen in cooler temperatures, raising risks of cracks in refrigerated areas. POF keeps its flexibility, offering steadier performance across storage types. Teams handling cold-chain products notice the difference in fewer breaks.

Polyethylene films bring solid bundling strength but usually fall short on clear views required for attractive displays. POF delivers a middle ground with both protective qualities and visual appeal suitable for customer-facing packages. Merchandisers prefer it for keeping shelf presentations crisp.

| Film Type | Clarity | Handling Strength | Application Flow | Recycling Path |

|---|---|---|---|---|

| POF | Clear | Consistent | Straightforward | Established |

| PVC | Fair | Changes in cold | Typical | More limited |

| Polyethylene | Reduced | Good for groups | Adaptable | Common |

Food and drink sections make frequent use of POF. It covers trays of fruits, vegetables, or deli products, maintaining condition while letting shoppers see contents. Beverage multipacks stay firmly together for easy shelving and carrying. Shelf stockers find these packs easier to arrange neatly.

Toy and game aisles apply the film to sets or boxed items, giving a sealed look that highlights packaging art. Small electronics accessories gain similar secure wrapping that signals untouched condition. Parents browsing often pick these up because everything looks fresh.

Personal care lines choose POF for its clean finish. Bottles or kits wrapped this way present neatly and protect against store dust. Display teams like how the shine matches lighting setups.

Everyday merchandise like notebooks, tools, or cleaning supplies gets bundled efficiently. The film keeps groups organized and shields from minor wear. Backroom organization improves with stable stacks.

Online order packing relies on POF to hold up through shipping routes, helping items arrive as expected. In mixed retail models blending in-store and online sales, the same film serves both channels without separate inventories. Fulfillment centers run smoother with one reliable material.

POF contributes to manageable expenses in retail packaging. Effective shrinkage means covering products adequately with reasonable material amounts. Buyers see value in rolls that go further.

Production lines move steadily with the film, cutting down on stops or adjustments. Fewer imperfect packages mean less material thrown away. Maintenance crews spend less time fixing issues.

Lower rates of damaged goods in transit save on replacements and handling. The neat appearance on shelves can encourage more customer interest and turnover. Sales floors report quicker movement of wrapped items.

Standard machines handle POF without major overhauls, keeping setup straightforward. Over time, these efficiencies add up for operations running multiple shifts or handling large volumes. Accounting notices the steady cost pattern.

Retail operations increasingly factor in material impact. POF fits recycling systems designed for polyolefins in many areas. Its lighter weight compared to some options reduces load during transport. Logistics teams track lower fuel use indirectly.

Careful application avoids excess usage, supporting efforts to cut waste. Brands aiming for responsible messaging often include POF in their packaging lineup. Marketing materials highlight the fit naturally.

Material improvements now offer versions containing recycled portions, extending options for retail sustainability. These developments allow gradual shifts without disrupting established processes. Procurement finds suppliers ready to meet growing requests.

Heat application requires attention to get even results without warping. Calibrated equipment handles this reliably in daily use. Technicians make small tweaks that become routine.

Premium versions carry higher pricing, but overall savings from efficiency often balance the difference. Matching film grade to specific products keeps costs in line. Purchasing agents learn which thickness suits most runs.

Staff familiarization with the material turns initial learning into smooth routine. Simple guidelines on roll loading and temperature settings go a long way in consistent outcomes. New hires pick it up fast.

Supermarkets wrap fresh sections with POF to keep items presentable longer on display. Electronics chains bundle cables or chargers securely for clean stocking.

Cosmetics counters create gift sets that hold together firmly while looking polished. Seasonal promotions, like holiday bundles, benefit from quick wrapping that maintains a festive appearance. Floor staff rearrange displays easily without tears. These cases demonstrate POF's fit for varied retail tasks.

Packaging trends lean toward materials that maintain performance alongside adaptability. Refinements in POF aim at better recycling and reduced weight to match shifting retail priorities. Suppliers respond to requests for updated rolls.

Adding printable surfaces or codes directly on the film could connect store items to digital details, blending physical and online shopping. Trial runs show promise in pilot stores.

Sustainable approaches will keep materials like POF relevant in future retail plans, especially as stores seek ways to combine practicality with broader goals. Buyers stay alert to viable changes.

Polyolefin shrink film earns its place in retail through practical clarity, strength, and ease of use. It aids protection and presentation across store types, serving as a solid option for current packaging needs.

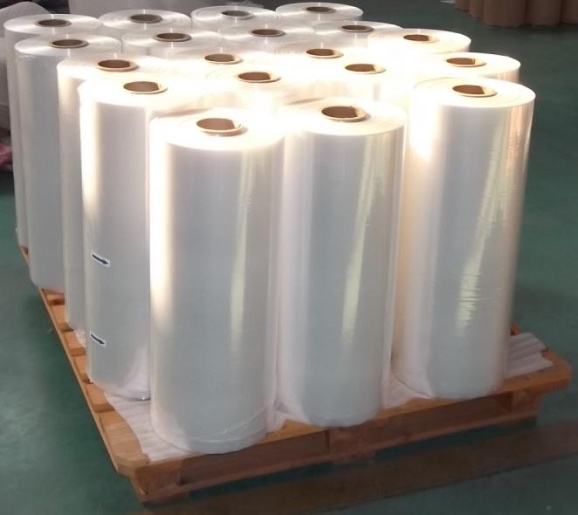

JTPackage operates as a dedicated manufacturing facility producing Polyolefin shrink films focused on retail applications. The factory maintains steady production standards to deliver materials that support clear, durable wrapping for various products.

Working with JTPackage provides access to films developed for retail performance, including options suited to food contact and general merchandise. The emphasis on quality control and application fit helps retailers maintain consistent packaging results across their operations.