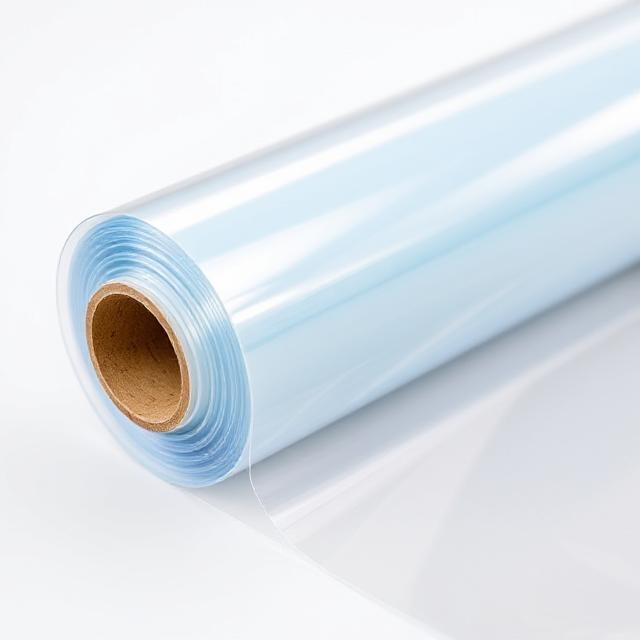

Wrapping film is a versatile and widely used material in the packaging industry, designed to protect, secure, and bundle products during transportation, storage, and distribution. It is made from various types of plastic, such as polyethylene or polypropylene, and is used in a variety of applications across different sectors.

Wrapping film refers to a thin, flexible plastic film that is primarily used to wrap or cover items. It can be applied manually or with the help of machines, providing a protective layer around goods. This protective covering prevents dirt, moisture, and other environmental elements from damaging the products while keeping them securely bound together. Wrapping films come in different forms, including stretch film, shrink film, and stretch wrap, each serving distinct purposes depending on the application.

Product Packaging

One of the most common uses of wrapping film is in packaging. Businesses often use it to wrap individual items or groups of products, especially for shipping and storage purposes. The film helps ensure that the products stay intact and protected during transit.

Pallet Wrapping

In warehouses and distribution centers, wrapping films are used to wrap entire pallets of goods. This process stabilizes the load, preventing individual items from shifting during transportation, and also helps secure them to the pallet, making the handling process more efficient.

Food Packaging

Wrapping film plays a crucial role in the food industry by preserving food quality. When wrapped around food products, it acts as a barrier that helps maintain freshness by keeping moisture in and contaminants out. In this application, specific types of wrapping films are used, which comply with food safety regulations.

Retail Packaging

Many products found on retail shelves, such as bottled goods, electronics, or small appliances, are wrapped in films to prevent damage and enhance the product's presentation. In retail settings, wrapping films also help prevent tampering, providing consumers with confidence in the product's integrity.

Storage and Organization

Beyond its role in shipping, wrapping film is also used for storage purposes. It is a quick and easy way to group items together, whether for long-term storage or during temporary organizing projects. This application helps save space, keeps items clean, and makes inventory management easier.

1. Flexibility and Stretchability

One of the standout features of wrapping film is its flexibility. The material is designed to be flexible, allowing it to conform tightly to the shape of the item or product being wrapped. Stretchability is also a key feature of many types of wrapping films, particularly stretch films. The ability to stretch the film allows it to tightly adhere to products, which provides greater stability during transportation. This stretchability also enables the film to expand and contract, providing a secure fit even for irregularly shaped items.

2. Durability and Strength

Wrapping film is known for its strength, which helps to ensure that goods remain secure throughout their journey. The film’s durable nature means it can withstand wear and tear, reducing the risk of punctures or tears that could compromise the integrity of the products being protected. This strength is particularly important in transit and storage, where products can be exposed to rough handling and environmental conditions.

3. Protection Against External Elements

One of the main reasons wrapping film is used is its ability to protect products from external elements. Wrapping film creates a barrier that shields goods from dust, dirt, moisture, and other contaminants, which helps maintain the quality of the product, especially for sensitive items like food or electronics. Additionally, some wrapping films offer resistance to UV rays, which can be beneficial when protecting items that may be exposed to sunlight during storage or transport.

4. Tamper-Evident Features

Certain types of wrapping film are designed to provide tamper-evident protection. This feature is particularly useful for securing goods during transit and providing assurance to both suppliers and consumers. The tamper-evident nature of some films means that if the packaging has been compromised, it will be immediately visible, reducing the chances of fraud and ensuring that the product is in its original condition upon arrival.

5. Cost-Effectiveness

Wrapping film is a cost-effective solution for packaging, especially when compared to other forms of packaging like boxes or hard containers. The material is lightweight, meaning it doesn't add significant weight to the overall shipment, thus reducing transportation costs. Additionally, wrapping film is relatively inexpensive to produce, making it an economical choice for businesses looking to package and ship products on a budget.

6. Transparency and Visibility

Many types of wrapping film are clear or transparent, allowing the contents to be easily visible without needing to open the packaging. This transparency is especially helpful in retail environments, where products can be displayed in their original packaging while still being protected. It also makes inventory management easier since the contents are visible and identifiable without unwrapping or disturbing the packaging.

7. Versatility in Application

Wrapping film is highly versatile and can be used for a wide range of applications across different industries. It can be used to wrap individual items, bundles, or even entire pallets of goods. Additionally, wrapping films come in different types to cater to specific needs. Stretch film, shrink film, and other variants each offer unique benefits depending on the specific requirements of the product or industry.

8. Environmental Considerations

While traditional plastic wrapping films have raised concerns regarding environmental impact, there has been a growing demand for eco-friendly alternatives. Many companies now offer biodegradable or recyclable wrapping films that help reduce the environmental footprint. These films maintain the core functionality of traditional wrapping films while being more sustainable and reducing the impact on landfills.

Wrapping film plays a critical role in food packaging and preservation, offering a combination of protective qualities that help extend shelf life, maintain freshness, and ensure the safety of food products during transportation and storage. In the food industry, proper packaging is essential not only for protecting food from contamination but also for preserving its quality and ensuring that it reaches consumers in optimal condition. Wrapping film has emerged as one of the most versatile and effective materials used in food packaging for these purposes. Below, we explore the various ways in which wrapping film contributes to food packaging and preservation.

1. Maintaining Freshness and Quality

One of the primary roles of wrapping film in food packaging is to maintain the freshness and quality of the food. The film acts as a barrier that helps prevent the loss of moisture, which is particularly important for perishable food items like fruits, vegetables, and meat. By sealing in the moisture, the film helps keep the food from drying out, which can cause it to lose flavor and texture. Similarly, for baked goods like bread or pastries, wrapping film helps maintain their softness and prevents them from becoming stale.

2. Protection from Contaminants

Food is susceptible to contamination from external elements such as dirt, dust, bacteria, and other harmful microorganisms. Wrapping film provides an essential protective layer that shields food from these contaminants, ensuring that it remains safe for consumption. The film helps prevent direct contact with surfaces, hands, and airborne particles, which could otherwise lead to spoilage or contamination of the food product. For ready-to-eat meals or snacks, this added protection is crucial for maintaining hygiene and food safety standards.

3. Extending Shelf Life

One of the most significant benefits of using wrapping film in food packaging is its ability to extend the shelf life of food products. Wrapping film helps control the exposure of food to oxygen, which can cause oxidation and spoilage. By reducing the contact with air, the film slows down the process of spoilage and helps preserve the food's taste, texture, and nutritional value for a longer period. This is particularly important for perishable items such as dairy products, meats, and prepared meals that are sensitive to oxidation.

4. Reducing Waste

The use of wrapping film in food packaging not only helps preserve the food but also reduces waste. By extending the shelf life of food products, wrapping film allows consumers to store food for a longer period without worrying about it spoiling quickly. This helps minimize food wastage, which is a significant issue for both businesses and households. For businesses, the ability to keep products fresher for longer periods also translates to reduced losses and better inventory management.

5. Tamper-Evident Protection

In food packaging, ensuring that the product has not been tampered with is critical for consumer trust and safety. Many types of wrapping films, especially those used for food packaging, include tamper-evident features. This means that if the packaging has been opened or compromised, it will be immediately apparent to the consumer. This feature is particularly important for packaged foods like snacks, beverages, and ready-to-eat meals, where consumers need to be confident in the integrity of the product they are purchasing.

6. Convenience and Portability

Wrapping film also provides significant convenience and portability, especially in the case of individually packaged food items. Products wrapped in film are easy to handle, transport, and store. The lightweight nature of the film ensures that packaging does not add unnecessary bulk to the product, while its flexibility allows it to conform to the shape of the food. This makes wrapped food items easy to carry, whether for on-the-go meals, snack packs, or meal prepping for the week.

7. Temperature Control

Certain wrapping films are designed to offer temperature control, which is vital for storing and transporting temperature-sensitive foods. For instance, some films are used in conjunction with refrigeration or freezing to help maintain the required temperature for perishable foods. By providing an additional layer of insulation, wrapping film helps prevent temperature fluctuations that could compromise the safety and quality of the food.

8. Sustainability in Food Packaging

In recent years, there has been a growing demand for more sustainable food packaging solutions, and wrapping films are no exception. Biodegradable and recyclable wrapping films are increasingly being developed to address environmental concerns, offering the same protective benefits while reducing the ecological impact of plastic packaging. This is particularly important for food businesses looking to align with sustainability practices and meet the expectations of eco-conscious consumers.

Wrapping films are widely used in various industries, from food packaging to logistics, thanks to their versatility and protective qualities. Different types of wrapping films are designed for specific purposes, each offering unique advantages depending on the application. Understanding these different types of films can help businesses select the most suitable option based on their needs.

1. Stretch Film

Stretch film is one of the most commonly used types of wrapping film, particularly in logistics and warehousing. This film is characterized by its ability to stretch significantly without breaking, providing a tight, secure wrap around products. Stretch film is typically used for palletizing goods, ensuring that items stay in place during storage and transportation. Its elasticity helps it cling to surfaces, preventing load shifting and providing stability.

Common uses:

Securing palletized goods

Bundling multiple products together

Packaging irregularly shaped items

Preventing dust and dirt from contaminating products

2. Shrink Film

Shrink film is designed to shrink tightly around a product when exposed to heat, creating a form-fitting, protective layer. The process of shrinking is typically done through a heat tunnel or heat gun, which causes the film to contract, hugging the contours of the item. Shrink film offers excellent protection against moisture, dust, and tampering, making it ideal for retail packaging, particularly for consumer goods.

Common uses:

Packaging products for retail sale

Shrink wrapping for food items, such as pre-packaged meats or snacks

Packaging bundled products or gifts

Providing tamper-evident packaging

3. Stretch Hood Film

Stretch hood film is a high-performance, stretchable plastic film often used for packaging and securing large, heavy loads, such as pallets of beverages, bottled water, or construction materials. Unlike traditional stretch film, which is applied directly to the load, stretch hood film is typically pulled over the top of the load and then stretched over the sides, creating a "hood" that covers the entire pallet.

Common uses:

Securing large and heavy loads in distribution centers

Wrapping construction materials and bulky goods

Protecting items from environmental elements like rain, dust, and dirt

4. Slip Sheet Film

Slip sheet film is a type of wrapping film used in combination with a slip sheet, which replaces traditional pallets in shipping and storage. It is a specialized film that can be used to secure products to the slip sheet, keeping the items stable and secure during transportation. Slip sheet film is often used in industries that deal with bulk shipments, such as agriculture or automotive parts.

Common uses:

Securing products on slip sheets for shipping

Packaging bulk goods or products with irregular shapes

Reducing packaging weight compared to traditional pallets

5. Polyolefin (POF) Shrink Film

Polyolefin shrink film is a specific type of shrink film made from a blend of polyolefin resins. It is known for its high clarity, durability, and superior strength. POF shrink film is popular in food packaging, particularly in cases where product visibility is important. It provides a smooth, tight finish, giving the product a polished appearance.

Common uses:

Food packaging, such as wrapped sandwiches or snacks

Retail product packaging, like DVDs, books, and electronics

Shrink wrapping promotional bundles or gift sets

6. Foil Wrap Film

Foil wrap film is used primarily for packaging food products. Made from aluminum foil or a combination of foil and plastic, it is often used to provide a high level of protection against light, moisture, and odors. This makes it ideal for foods that require long-term preservation, such as meats, cheeses, or frozen products.

Common uses:

Wrapping meats or cheeses for preservation

Packaging frozen food items

Providing a protective layer for heat-sensitive products

7. Antistatic Film

Antistatic film is a specialized type of wrapping film used to protect sensitive electronic components from static electricity. This film prevents the buildup of static charges, which can damage electronic parts. Antistatic film is commonly used in industries dealing with electronics, such as computers, circuit boards, and other delicate devices.

Common uses:

Packaging electronic components and parts

Preventing static buildup during shipping and handling of sensitive equipment

Safeguarding delicate machinery or devices during storage

8. Biodegradable and Compostable Films

With the increasing demand for eco-friendly packaging options, biodegradable and compostable wrapping films are becoming more popular. These films are made from renewable resources and break down more quickly than traditional plastic films, helping to reduce environmental impact. They are often used in food packaging and consumer goods, where sustainability is a key concern.

Common uses:

Food packaging for fresh produce, snacks, or frozen foods

Eco-friendly packaging for retail products

Wrapping for consumer goods where sustainability is a priority

| Type of Wrapping Film | Common Uses |

|---|---|

| Stretch Film | Palletizing goods, bundling products, preventing contamination |

| Shrink Film | Retail packaging, tamper-evident packaging, packaging food items |

| Stretch Hood Film | Securing heavy loads, protecting large items from the elements |

| Slip Sheet Film | Securing products on slip sheets, bulk shipping, reducing weight |

| Polyolefin (POF) Shrink Film | Food packaging, retail product packaging, shrink-wrapping promotional bundles |

| Foil Wrap Film | Wrapping food items, long-term preservation, providing moisture protection |

| Antistatic Film | Packaging electronic components, preventing static damage |

| Biodegradable and Compostable Films | Eco-friendly food packaging, retail products, sustainability packaging |

When it comes to packaging, two of the most popular options are wrapping film and shrink wrap. Both are versatile materials used for securing, protecting, and organizing products during storage and transportation, but they have distinct features and applications. Understanding the differences between these two types of packaging materials can help businesses make an informed decision based on their specific needs.

What is Wrapping Film?

Wrapping film, often referred to as stretch film, is a highly elastic material that stretches and clings to products or palletized goods. It is typically used for securing items together, such as wrapping multiple products in a bundle or stabilizing goods on a pallet. Wrapping film is particularly known for its flexibility and the way it adheres tightly to surfaces, without the need for heat or additional equipment.

Key Characteristics of Wrapping Film:

Stretchable: The film can stretch to several times its original length, making it highly adaptable to different shapes and sizes.

Transparent: Wrapping film is typically clear, allowing the contents to be visible without opening the package.

Easy to Apply: Wrapping film can be applied by hand or with a wrapping machine, making it convenient for both small and large-scale packaging needs.

What is Shrink Wrap?

Shrink wrap is a plastic film that shrinks tightly around an object when exposed to heat. Unlike wrapping film, shrink wrap requires the application of heat to activate its shrinking properties, which creates a tight, custom-fit seal around the product. This makes shrink wrap particularly ideal for securing products that need to be completely covered and protected, such as retail products or bundled items.

Key Characteristics of Shrink Wrap:

Heat Activation: Shrink wrap requires the use of heat, typically from a heat gun or heat tunnel, to shrink and form a tight fit around the product.

Durable and Tamper-Evident: Once shrunk, the film forms a rigid, secure layer around the product, providing a clear, tamper-evident seal.

Versatile for Various Shapes: Shrink wrap conforms to the exact shape of the product, offering a snug and tight seal, even for irregularly shaped items.

Comparison of Wrapping Film and Shrink Wrap

While both wrapping film and shrink wrap offer excellent protective qualities, their specific applications and benefits vary depending on the nature of the product and the intended use. Below is a detailed comparison of these two packaging materials:

| Feature | Wrapping Film | Shrink Wrap |

|---|---|---|

| Application Method | Applied by stretching over the product manually or using a machine | Requires heat to shrink and tightly conform to the product |

| Type of Protection | Provides a flexible, secure hold, ideal for stabilizing palletized goods or bundling products together | Offers a rigid, tamper-evident seal, perfect for full coverage and protection against contaminants |

| Visibility of Contents | Transparent, allowing visibility of contents without unwrapping | Transparent, providing full visibility once shrunk around the product |

| Durability | Durable but not as tight or form-fitting as shrink wrap | Creates a tight, protective layer that is more durable and tamper-proof |

| Common Uses | Bundling products, securing items on pallets, protecting goods from dirt and moisture during transport | Retail packaging, food packaging, securing irregularly shaped items, tamper-evident packaging |

| Cost-Effectiveness | Cost-effective and efficient for large-scale packaging | Slightly higher cost due to the need for heat equipment, but offers superior protection and presentation |

| Ease of Use | Easier to apply, can be done manually or with machines | Requires heating equipment for application, which can add complexity to the process |

| Environmental Impact | Can be made from recyclable materials, but not always biodegradable | Often made from materials that can be recycled, but not always biodegradable |

When to Use Wrapping Film?

Wrapping film is an ideal choice when:

You need to secure products together or stabilize loads, such as for palletizing or bundling.

The packaging process requires flexibility and ease of application.

You are shipping products that need protection from dirt and moisture but don't require a tamper-proof seal.

You need to package items quickly and efficiently without requiring specialized heat-sealing equipment.

When to Use Shrink Wrap?

Shrink wrap is the best option when:

You need to provide full coverage and a tight seal around the product for protection against contaminants.

Tamper-evident packaging is important for consumer goods, ensuring product integrity.

The product is irregularly shaped and requires a custom fit.

You are packaging items for retail, where presentation and protection are key factors.

You need the packaging to be durable and offer long-term protection, such as for electronics or high-value items.

Choosing the right wrapping film for your business can be a crucial decision that impacts both the effectiveness of your packaging and the overall cost-efficiency of your operations. Whether you are packaging food, electronics, or industrial products, the wrapping film you select will play a significant role in protecting goods, ensuring safe transport, and maintaining product integrity. With so many different types of wrapping films available, it's important to consider a few key factors before making your choice. Here's a guide to help you choose the best wrapping film for your business needs.

1. Understand the Nature of the Product

The type of product you are packaging is one of the most important factors in determining the right wrapping film. Different products have different requirements for protection, visibility, and shelf life. For instance, food items may require films that provide moisture control and preserve freshness, while electronics need films that offer anti-static properties to prevent damage from static electricity.

For food items: Choose films that help preserve freshness and protect against moisture, contaminants, and UV light. Food-grade films are often required to meet specific safety standards.

For electronics: Opt for antistatic films to protect sensitive components from static discharge.

For industrial products: Strong and durable films that can withstand rough handling or extreme conditions are essential.

2. Consider the Type of Protection Required

Different wrapping films provide varying levels of protection, so understanding what type of protection your product needs is critical. For example, if you need a product to stay intact and secure during transit, stretch film or shrink wrap might be the right choice. If tamper-evident packaging is required for retail products, shrink wrap would be a better fit. Here are some considerations for protection:

Moisture protection: Stretch films and shrink wraps can offer moisture protection depending on the application.

Tamper resistance: Shrink wrap is commonly used for tamper-evident packaging, which is important for retail and consumer goods.

Dust and dirt protection: Wrapping films are excellent for protecting products from dirt and dust during transportation, especially when used for palletizing or bundling.

3. Evaluate the Transparency and Visibility of the Product

Visibility of the product inside the packaging can be important for both marketing and functionality. Transparent wrapping films allow consumers to see the product without opening the package, which can be an advantage in retail environments. Additionally, it can be useful for inventory management and quality control.

For retail packaging: Choose a clear wrapping film that allows consumers to view the product.

For bulk shipping or storage: The level of transparency may be less important, but you may still need clear or semi-transparent films for easy identification.

4. Assess the Environmental Impact

With growing awareness of environmental concerns, many businesses are moving toward eco-friendly alternatives. When selecting wrapping film, consider the environmental impact of the material. Look for films that are recyclable, biodegradable, or made from renewable resources.

Eco-friendly options: Many businesses are opting for biodegradable or compostable films, especially for food packaging, to reduce their environmental footprint.

Sustainability: Choose films that can be recycled to align with sustainability goals and consumer demand for eco-conscious products.

5. Consider Ease of Application and Cost

The ease of use and application is another factor to consider when choosing the right wrapping film. For small-scale operations, manual wrapping might be more practical, while larger businesses may benefit from automated wrapping machines that can apply the film more quickly and efficiently.

Manual application: Stretch films are often easy to apply by hand, making them a good option for smaller businesses or operations with limited packaging volume.

Automated wrapping: Shrink wraps and stretch films can also be applied using machines, but shrink wrap requires additional equipment, such as heat guns or heat tunnels, which can increase costs.

Additionally, consider the overall cost-effectiveness of the wrapping film. While eco-friendly options might be more expensive upfront, they could provide long-term savings through reduced waste and improved customer satisfaction. Evaluate your budget to find the best balance between cost and functionality.

6. Size and Strength of the Film

The size of the film roll and its strength are important considerations, especially if you are packaging heavy or bulky products. Stronger films, like certain types of stretch or shrink films, are necessary for securing larger items or pallet loads. Likewise, the width and length of the film roll should match the scale of your packaging operation.

For smaller items or retail packaging: Standard-width films may be suitable.

For larger or heavier products: Opt for stronger, industrial-grade films that can securely wrap heavy items.

7. Regulatory and Safety Requirements

Depending on your industry, there may be regulatory or safety standards that the wrapping film must meet. This is especially true in food packaging, pharmaceuticals, or medical products, where the materials must be food-safe, non-toxic, and compliant with industry regulations. Always ensure that the wrapping film meets the required standards for your specific application.

For food products: Look for films that are FDA-approved or meet local food safety standards.

For medical or pharmaceutical items: Make sure the wrapping film complies with health and safety regulations for those industries.

8. Compatibility with Other Packaging Materials

Consider how your wrapping film will work with other packaging materials you may be using. For example, if you are using cardboard boxes, the wrapping film should be able to secure the box tightly without damaging it. Similarly, if you are combining different types of packaging (e.g., combining shrink wrap with foam inserts), ensure compatibility between materials for optimal results.

| Factor | Considerations |

|---|---|

| Nature of the Product | Food, electronics, industrial products, etc. |

| Type of Protection | Moisture, tamper resistance, dust protection, etc. |

| Visibility | Clear films for retail packaging, or opaque for bulk shipping |

| Environmental Impact | Recyclable, biodegradable, or eco-friendly materials |

| Ease of Application & Cost | Manual vs. automated wrapping, cost vs. efficiency |

| Size and Strength | Choose based on product size, weight, and wrapping needs |

| Regulatory & Safety Requirements | Compliance with industry standards, food safety, etc. |

| Compatibility with Other Materials | Compatibility with other packaging materials (boxes, inserts) |

1. Durability and Strength

One of the main reasons stretch wrap film is preferred is its remarkable durability. Stretch film is designed to stretch up to several times its original length, making it exceptionally strong when wrapped around products. This stretchability provides excellent holding power, ensuring that products remain tightly secured and stable during transportation. It is resistant to tears and punctures, which is crucial when goods are subjected to rough handling during shipping.

2. Cost-Effectiveness

Stretch wrap film is highly cost-effective compared to other packaging materials such as boxes, crates, or rigid packaging. Its lightweight nature helps reduce shipping costs because it doesn't add significant weight to the overall load. Additionally, stretch wrap film is often used to secure multiple items together, eliminating the need for separate packaging for each item, further lowering costs. Businesses can achieve greater efficiency and savings by using stretch film for bundling and securing products during shipping.

3. Flexibility and Adaptability

Stretch wrap film is incredibly versatile and can be used for a wide variety of products, regardless of shape or size. Whether you are securing boxes, bundling irregularly shaped items, or wrapping large, heavy loads, stretch film can be easily adapted to meet the specific needs of the products. This flexibility makes it a go-to choice for industries that deal with a diverse range of items, from small retail products to large machinery or construction materials.

4. Enhanced Product Protection

Stretch wrap film offers excellent protection for products in transit. It acts as a barrier against dust, dirt, moisture, and other environmental contaminants that could damage goods during shipping. For industries dealing with food or electronics, the protective qualities of stretch film are especially important as they help maintain the integrity of the products. The film also provides an additional layer of security against tampering, making it ideal for valuable goods or sensitive products.

5. Improved Load Stability

In shipping and logistics, ensuring that items stay secure and do not shift during transit is critical. Stretch wrap film plays a crucial role in improving load stability. When applied to palletized goods, the film tightly binds items together, preventing them from moving, tipping, or collapsing during transportation. This not only reduces the risk of damage to the products but also enhances safety during handling, minimizing the chances of accidents in warehouses and transportation.

6. Ease of Application

One of the standout features of stretch wrap film is its ease of application. It can be easily applied by hand or with the help of automated machines, making it suitable for both small-scale operations and large-scale packaging needs. Stretch film can quickly be wrapped around items, ensuring a fast and efficient packaging process. This ease of use increases productivity, allowing businesses to streamline their packaging operations and focus on other critical aspects of their supply chain.

7. Space-Saving Benefits

Stretch wrap film is ideal for optimizing storage and shipment efficiency. It allows businesses to bundle multiple items together in a compact, organized manner, saving valuable space during storage and transportation. For companies that deal with large volumes of products, this space-saving feature can lead to better inventory management and reduced storage costs.

8. Recyclability and Environmental Considerations

With growing environmental concerns, many businesses are now focusing on sustainable packaging solutions. Stretch wrap film is available in recyclable options, making it a more eco-friendly choice compared to other types of plastic. Many manufacturers are also producing stretch film from post-consumer recycled materials, helping reduce the environmental impact of packaging waste. For businesses looking to align with sustainability initiatives, stretch wrap film offers an environmentally responsible packaging solution.

9. Tamper-Evident Features

In some industries, especially in the retail sector, security and tamper-evident packaging are of utmost importance. Stretch wrap film is a simple yet effective solution for ensuring that products are tamper-proof during transit. Once the film is applied, any attempts to open or tamper with the product will be easily visible, providing added security and peace of mind for both businesses and consumers.

Stretch wrap film is the preferred choice for packaging and shipping due to its versatility, durability, cost-effectiveness, and protective qualities. It offers excellent protection for products, improves load stability, and streamlines packaging processes, making it a popular option across various industries. Whether you are shipping retail goods, food products, or industrial equipment, stretch wrap film provides a reliable and efficient solution.

If you're looking for high-quality stretch wrap film, visit jtpackage.com or come see our factory, Jiuteng Shrink Film Factory, to explore our range of packaging solutions. We provide top-notch wrapping films that can help streamline your packaging operations and ensure your products reach their destination in perfect condition.