Industry Knowledge About & Product

A Guide to Polyolefin Shrink Films - Jiuteng Packaging&Wrapping

Polyolefin Shrink Films are now sought Shrink Films in the Packaging Industry. These shrink films offer 80% shrinking properties (both directions) along with better transparency and remains odourless when heated and cooled. POF Shrink Films does not emit Chloride on heating, this is an important advantage over PVC Shrink Films.

What is Polyolefin Shrink Film (POF Shrink Film) Made From?

Polyolefin Shrink Film (POF Shrink Film) is a versatile, heat-shrinkable material primarily made from a blend of polyethylene (PE) and polypropylene (PP). The film is created through a process called extrusion, where these polymers are melted and formed into thin, transparent films. The key component of POF is the combination of copolymerization between polyethylene and polypropylene, which gives the film its strength, clarity, and elasticity.

Polyethylene (PE) provides the film with a smooth surface and exceptional strength.

Polypropylene (PP) contributes to the film's high shrinkage rate, flexibility, and resilience.

Why Did Polyolefin Shrink Film Become Popular?

Polyolefin Shrink Film has gained widespread popularity due to its combination of versatility, performance, and eco-friendly attributes.

Excellent Shrinkage Properties: POF films offer high shrinkage rates, allowing them to conform tightly around products of various shapes and sizes.

Superior Strength and Durability: Compared to other shrink films, POF provides higher tensile strength, reducing the risk of tears during transport and handling.

Non-Toxic and Safe: Polyolefin is non-toxic, making it suitable for food packaging applications where safety is a top priority. This is a significant advantage over other shrink films, such as PVC.

Environmental Friendliness: POF is considered more eco-friendly than PVC shrink film, as it is free from harmful plasticizers and chlorine. It is also recyclable, which reduces its environmental impact.

Clarity and Gloss: Shrink Film offers clarity and a glossy finish, making it ideal for showcasing products with high visual appeal.

Heat Resistance: POF is highly heat-resistant, allowing it to be used in a wide range of applications without compromising its structural integrity.

Key Reasons to Choose Jiuteng Polyolefin Shrink Film

Exceptional Clarity & Presentation: Jiuteng's film is engineered for gloss and transparency, helping to enhance shelf visibility and give products a clean, professional finish.

Strong & Flexible Protection: Our polyolefin film offers tensile strength and puncture resistance, ensuring your products remain secure through transportation, storage, and handling.

Smooth & Consistent Shrink Performance: Whether you're packaging lightweight items or multi-product bundles, Jiuteng's shrink film provides uniform shrinkage without wrinkling or distortion.

Compatible With All Machinery: Designed for versatility, it works seamlessly with manual, semi-automatic, and fully automatic shrink wrap systems, reducing downtime and boosting output.

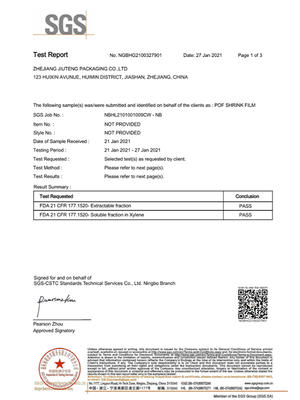

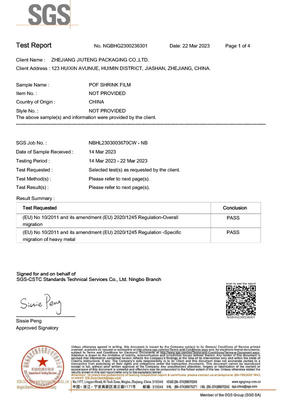

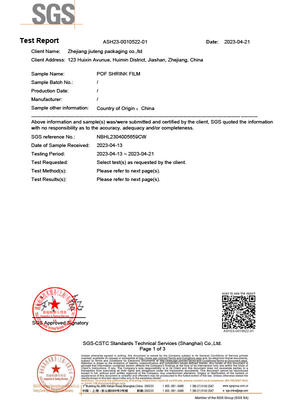

Food-Grade & Eco-Friendly: Free from harmful substances like chlorine, Jiuteng's Polyolefin film is safe for direct food contact and fully recyclable, making it a smart choice for environmentally conscious packaging operations.

Reliable Supply & Customization: With robust manufacturing capacity and strict quality control, Jiuteng ensures stable supply, tailored roll sizes, and custom options to meet your unique production needs.

What Are the Raw Materials Used in Shrink Film?

Shrink films are made from a variety of polymers, each offering different benefits. The primary raw materials used in shrink film production include:

Polyethylene (PE): The most commonly used material in shrink films due to its cost-effectiveness and durability.

Low-Density Polyethylene (LDPE): Provides a soft and flexible shrink film, used for packaging applications that do not require extreme strength.

High-Density Polyethylene (HDPE): Offers stronger, more rigid shrink films for heavy-duty applications.

Polypropylene (PP): Often used in Polyolefin Shrink Films because of its high shrinkage rate, clarity, and strength. It provides better heat resistance than polyethylene and offers a smoother finish.

Polyvinyl Chloride (PVC): PVC is used in some shrink films but has largely been replaced by Polyolefin films in many applications due to the environmental concerns associated with chlorine emissions from PVC.

Other Additives:

Plasticizers: Used to enhance flexibility in some shrink films.

UV Stabilizers: Protect the film from degradation due to exposure to sunlight.

Anti-Static Agents: Prevent static accumulation during the packaging process.

Colorants: To provide a colored or opaque finish if needed for branding or aesthetics.

A Comparison of Polyolefin Shrink Film and PVC Shrink Film: Advantages and Benefits

| Feature |

Polyolefin Shrink Film (POF) |

PVC Shrink Film |

| Environmental Impact |

Eco-friendly, recyclable, chlorine-free. |

Contains chlorine, non-recyclable, harmful emissions when burned. |

| Clarity |

High clarity, glossy finish, ideal for product display. |

Excellent clarity, but less glossy compared to POF. |

| Strength |

High tensile strength, resistant to tears. |

Weaker tensile strength, more prone to tears. |

| Shrinkage Rate |

Excellent shrinkage with high stretch properties. |

Moderate shrinkage rate, less stretch. |

| Durability |

Better durability in various weather conditions. |

Prone to cracking in low temperatures. |

| Safety |

Non-toxic, food-safe. |

Contains toxic additives, not suitable for food packaging. |

| Cost |

Slightly higher in price but offers better performance. |

Cost-effective, lower price point. |

| Heat Resistance |

High heat resistance, suitable for a wide range of applications. |

Lower heat resistance, not suitable for high-temperature items. |

Why Choose Polyolefin(POF) Shrink Film?

Here's why Polyolefin Shrink Film (POF) is the preferred choice for packaging in a wide range of industries:

Superior Performance

POF Shrink Film offers higher tensile strength and better shrinkage properties than PVC, which helps to provide a tight, secure fit around products. Its ability to conform to products of various shapes and sizes makes it ideal for both simple and intricate packaging needs.

Environmental Benefits

Polyolefin is chlorine-free, unlike PVC, making it more environmentally friendly. It can also be recycled, which reduces the environmental impact associated with waste disposal. As sustainability becomes a key factor for consumers and manufacturers alike, POF's eco-friendly nature gives it an edge over PVC in the market.

Safety and Non-Toxicity

POF Shrink Film is non-toxic, making it ideal for food packaging and pharmaceutical products. It doesn't release harmful chemicals like PVC does, offering peace of mind to consumers and manufacturers looking to maintain high safety standards.

Cost-Effectiveness

While POF may have a slightly higher initial cost compared to PVC, the benefits of greater strength, environmental safety, and better heat resistance often outweigh the price difference. Its ability to reduce breakage and increase product protection during transport makes it a more cost-effective solution in the long run.

Aesthetically Pleasing

POF Shrink Film offers clarity and gloss, enhancing the product’s visual appeal. Whether used for consumer goods, electronics, or food packaging, the high-quality finish of POF ensures that your product looks more appealing to consumers and retains its shelf value longer.

Versatility

POF Shrink Film can be used in a variety of applications, ranging from food and beverage packaging to consumer electronics, toys, and medical supplies. It is suitable for products with irregular shapes and is capable of handling a variety of packaging designs.

Polyolefin Shrink Film (POF) has rapidly become the material of choice for packaging due to its performance, versatility, and environmental benefits. Compared to PVC, POF offers strength, safety, and aesthetic appeal, making it the preferred option for businesses seeking high-quality, eco-friendly, and cost-effective packaging solutions.

By choosing POF Shrink Film, companies can improve product protection, enhance visual appeal, and reduce environmental impact, all while maintaining a high level of operational efficiency. Whether for retail packaging, bulk packaging, or export requirements, POF is a versatile and reliable choice for packaging solutions.

What Makes Polyolefin Shrink Film a Preferred Choice for Packaging?

Polyolefin shrink film is preferred for its high clarity, smooth shrinkage, and strong durability. It provides a professional appearance and tight seal, making it ideal for retail and food packaging.

Is Polyolefin Shrink Film Safe for Food Packaging?

Yes. Polyolefin shrink film is non-toxic, odorless, and approved for direct food contact. It is a safer and cleaner alternative to PVC.

Can Polyolefin Shrink Film Be Used on Automatic Packaging Machines?

Absolutely. It is compatible with manual, semi-automatic, and high-speed automatic machines, offering flexibility in various production lines.

What Products Can Be Packaged with Polyolefin Shrink Film?

It is widely used for food, cosmetics, electronics, printed materials, toys, and more. Its adaptability makes it suitable for many industries.

Can Polyolefin Shrink Film Be Used for Custom Packaging?

Yes, Polyolefin shrink film is highly customizable. It can be supplied in various thicknesses, widths, and lengths to meet specific packaging needs, and can even be printed for branding or promotional purposes.

How Durable is Polyolefin Shrink Film?

Polyolefin shrink film is extremely durable, with high resistance to punctures, tears, and abrasions. It maintains its integrity and protective qualities during shipping, storage, and handling.

Is Polyolefin Shrink Film an Eco-Friendly Option?

Yes, Polyolefin shrink film is environmentally friendly. It is made from recyclable materials, and unlike PVC, it does not release harmful chemicals when incinerated. This makes it an excellent choice for companies looking to reduce their carbon footprint.

What is the Shrinkage Ratio of Polyolefin Shrink Film?

Polyolefin shrink film typically offers a 50-75% shrinkage in both directions when heat is applied, depending on the product’s thickness and the heat level used. This ensures a tight, professional fit around your product.

What Are the Various Types of Polyolefin Shrink Films and Their Benefits?

Polyolefin shrink films are available in several types, including single-wound, centerfold, and perforated films. Each type is designed to meet specific packaging needs, offering advantages such as ease of application, protection, and enhanced visual presentation for different products.

Does Polyolefin Shrink Film Offer UV Protection?

Yes, Polyolefin shrink film offers some level of UV protection, which helps protect sensitive products from harmful UV rays during transportation and storage. This is particularly beneficial for items like cosmetics, food products, and electronics.

Can Polyolefin Shrink Film Be Used for Both High-Speed and Low-Speed Applications?

Yes, POF shrink film is highly versatile and can be used for both high-speed and low-speed applications. Its smooth shrinkage and easy handling make it compatible with a variety of machines, from small manual setups to high-volume automatic lines.

What Is the Shelf Life of Polyolefin Shrink Film?

Polyolefin shrink film has a long shelf life, typically 12-18 months when stored properly. The film should be kept in a cool, dry place away from direct sunlight to maintain its quality and performance.

Can Polyolefin Shrink Film Be Used in Combination with Other Packaging Materials?

Yes, Polyolefin(POF) shrink film can be combined with other packaging materials such as corrugated boxes, cardboard, or even rigid plastic containers. It provides an extra layer of protection while enhancing the overall presentation and security of the package.

What Factors Should Be Considered When Choosing the Right Polyolefin Shrink Film?

When selecting the ideal Polyolefin(POF) shrink film , factors such as product size, shape, machine compatibility, and desired shrinkage level must be considered. Additionally, the film's thickness, clarity, and durability play a crucial role in ensuring protection and visual appeal for the packaged items.

Can Polyolefin Shrink Film Be Used for Both Small and Large-Scale Packaging Operations?

Yes, POF shrink film is highly versatile and suitable for both small-scale and large-scale packaging operations. Its flexibility makes it compatible with a range of packaging machines, from manual setups for small batches to high-speed automated lines for large-volume production.

简体中文

简体中文

Home

Home